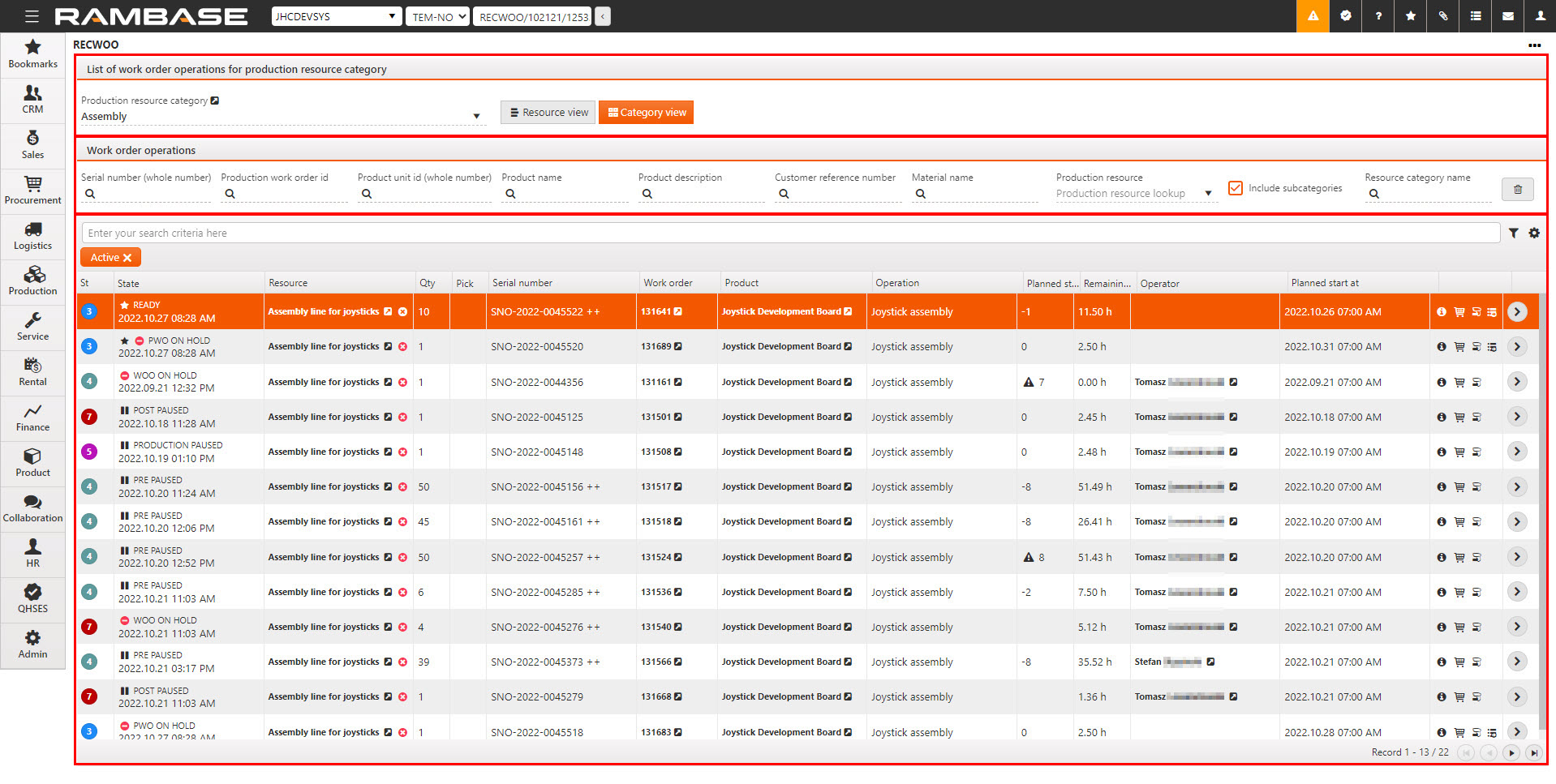

The List of work order operations for production resource category (RECWOO) application

The List of work order operations for production resource category (RECWOO) application is for efficiently sorting through Work order operations (WOO) organized by Production resource categories (REC).

Navigate to the application

Option 1: Click the Program field and type "RECWOO" and press ENTER.

Click here to read more about the user interface.

The following areas are described in the sections below:

The List of work order operations for production resource category area

The Work order operations area

Header

List

Context menu options

The List of work order operations for production resource category area

The List of work order operations for production resource category area is used to select the intended Production resource category (REC) to view Work order operations (WOO) for. The user can also click on the Resource view button to open the Operators list of production work order operations (RWOO) application and view Work order operations (WOO) organized by their related Production resource (RESCONFIG).

Production resource category drop-down menu - Click the Production resource category drop-down menu to select the intended Production resource category (REC) and display the related Work order operations (WOO).

Resource view button - Click the Resource view button to open the Operators list of Production work order operations (RWOO) application.

Category view button - Click the Category view button to open the List of work order operations for production resource category (RECWOO) application.

The List of work order operations for production resource category area

Header

After selecting the intended Production resource category (REC) in the List of work order operations for production resource category area, the user can further filter the list by using the options in the Work order operations header area. The Work order operations area contains fields, drop-down menus and buttons to help the user list only the intended Work order operations (WOO).

Field, drop-down menu or button | Description |

|---|---|

Serial number (whole number) - field | To list information on a specific Work order operation (WOO), the user can type the serial number of the intended Product unit (LCM) being produced by the Work order operation (WOO). Note that the complete serial number must be entered. |

Production work order id - field | To list information on a specific Work order operation (WOO), the user can type Production work order (PWO) identifier. Only type numbers. Note that this is the same number listed in the Work order column in the Work order operations list. |

Product unit id (whole number) - field | To list information on a specific Work order operation (WOO), the user can type the Product unit (LCM) identifier. Only type numbers. |

Product name - field | To list information on specific Work order operations (WOO), the user can type the name of an intended Product (ART) to list only Work order operations (WOO) producing products with names containing the typed values. |

Product description - field | To list information on specific Work order operations (WOO), the user can type the description an intended Product (ART) to list only Work order operations (WOO) producing products with descriptions containing the typed values. |

Customer reference number - field | To list information on specific Work order operations (WOO), the user can type the customer reference number of a Sales order (COA), that has triggered the Production work order (PWO) and Work order operation (WOO), to list only Work order operations (WOO) containing the customer reference number. |

Material name - field | To list information on specific Work order operations (WOO), the user can type the name of parts to list only Work order operations (WOO) with part name containing the typed values. |

Production resource drop-down menu | Click on the Production resource drop-down menu to filter on a specific Production resource (RESCONFIG). |

Include subcategories checkbox | Click on the Include subcategories checkbox to display Work order operations (WOO) linked to all subcategories below the selected Production resource category (REC). |

Resource category name field | The Resource category name field is used to filter on Production resource categories (REC) with the same name, showing all Work order operations (WOO) assigned to those Production resource categories (REC) Example

Note that the Include subcategories checkbox must be selected for this field to be available. |

| Click the Clear filter button to remove all selected parameters in the Work order operations area. |

List

The list in the Work order operations area will list all Work order operations (WOO) for the selected Production resource category (REC) based on the selections made in the header. The user can also customize which columns are to be displayed by using the Column settings.

The user can also further filter the Work order operations (WOO) displayed by using the Filter builder where the user can select from standard filters or even create custom filters. The standard filters and the available columns are described in the tables below.

Search field - The Search filed can be used to search for specific Work order operations (WOO). Click the Search field and press SPACEBAR to list all the available parameters to search on.

Filter builder - Click the Filter builder icon to open a popup where the user can select filters from the Standard filters area. Selected filters will be visible below the Search field. Active filters are marked orange, inactive are marked gray. The user can also Create custom filters by selecting Field, Operator and Value in the Create custom filters area, and then pressing the Save filter button. Saved filters will be available from the My saved filters area. Click the intended saved filter to add it below the Search field.

Standard filters and their descriptions are listed in the table below:

Standard filters

Description

Active

Will display Work order operations (WOO) in:

Status 3 (Ready for start)

Status 4 (Changeover setup)

Status 5 (Processing)

Status 7 (Changeover cleanup)

All

Will display Work order operations (WOO) in:

Status 2 (In queue)

Status 3 (Ready for start)

Status 4 (Changeover setup)

Status 5 (Processing)

Status 7 (Changeover cleanup)

Can be grouped

Will display Work order operations (WOO) that are not grouped in the Group work order operations (GWOO) application and are in:

Status 2 (In queue)

Status 3 (Ready for start)

Completed

Will display Work order operations (WOO) in:

Status 9 (Completed)

Grouped

Will display Work order operations (WOO) that are grouped in the Group work order operations (GWOO) application and are in:

Status 2 (In queue)

Status 3 (Ready for start)

Status 4 (Changeover setup)

Status 5 (Processing)

Status 9 (Completed)

My tasks

Will display Work order operations (WOO) where the user is set as an operator.

Not grouped

Will display Work order operations (WOO) that are not grouped with the Group work order operations (GWOO) application and are in:

Status 3 (Ready to start)

Status 5 (Processing)

Status 9 (Completed)

Production

Will display Work order operations (WOO) in:

Status 4 (Changeover setup)

Status 5 (Processing)

Status 7 (Changeover cleanup)

Ready

Will display Work order operations (WOO) in:

Status 3 (Ready)

Wait

Will display Work order operations (WOO) in:

Status 2 (In queue)

Column settings - Click the Column settings icon to:

Export to excel - Will send an .xlsx file by email to user. The email is set up in the Personnel (PER) application.

Reset to default view - Reset all changes to selected columns and resizing of the area. This is useful if encountering unexpected errors.

Columns - Hover over to select which columns should be displayed in the list. The available columns are described in the table below.

Columns

Description

St

Displays an icon indicating the status of the Work order operation (WOO). Hover over for a description of the status.

State

The State column includes informative icons and text further detailing the status of the Work order operation (WOO). The Ready at date and time is also displayed if the Ready at date is defined.

Star icon - High priority

Stop icon - Work order operation (WOO) and/or Production work order (PWO) is on hold.

Pause icon - Work order operation (WOO) and/or Production work order (PWO) in paused.

Resource

Displays the name of Production resource (RESCONFIG) assigned to the Work order operation (WOO). Click the View to open the Production resources (RESCONFIG) application to view and edit details on the selected Production resource (RESCONFIG). If there has been set a production resource condition, a warning icon will be displayed in the column.

Read more about Setting a resource condition in the Work order operations (WOO) application here.

Qty

The quantity of Product units (LCM) being produced by the initial Production work order (PWO), set when creating the Production work order (PWO).

Pick

The Pick column displays icons indicating the status of the picking process for the Work order operation (WOO).

All remaining parts are ready for picking.

Some parts are ready for picking.

Some parts are not purchased.

All parts are not in stock.

Serial number

Displays the serial number of the Product unit (LCM) being produced by Work order operation (WOO). If there are multiple Product units (LCM) being produced, ++ will be displayed at the end of the serial number.

Work order

Displays the identifier of the Production work order (PWO) for the Work order operation (WOO).

Customer

If the Production work order (PWO) and the subsequent Work order operations (WOO) are linked to a Sales order (COA), the name of the customer will be displayed in the Customer column.

Customer reference number

If the Production work order (PWO) and the subsequent Work order operations (WOO) are linked to a Sales order (COA), the customer reference number will be displayed in the Customer reference number column.

Product

The name of Product (ART) being produced is displayed in the Product column. Click the View icon to open the Product (ART) application to view and edit details on the Product (ART).

Revision

Gives information about the current revision of the product. The revision number is derived from the Product (ART) application. From the Product (ART) application, click on the View icon next to the Revision field in the header to view Article revisions.

Operation

Displays the name of the Production operation (OPR).

Planned start at margin

Displays the number of days in relation to the Scheduled completion date set in the Production work order (PWO) application when creating the Production work order (PWO). A positive number will be displayed if the number of days has passed the Scheduled completion date. If the Scheduled completion date is a future date, a negative number will be displayed, counting down until the Scheduled completion date.

Remaining time

Displays the remaining time for the operations set in the Product (ART) structure. Details can be quickly viewed by clicking the View icon in the Work order column and then clicking the Structure button in the Links area, in the Production work order (PWOD) application.

Operator

Displays the name of the operator who last worked on the current Work order operation (WOO). Click the View icon to open the Personnel (PER) application to view details about

Planned start at

The date which the Work order operation (WOO) is planned to start to meet the required date set when creating the Production work order (PWO).

Planned finished at

The date which the Work order operation (WOO) is planned to be completed, to meet the required date set when creating the Production work order (PWO).

Finished at

The date which the Work order operation (WOO) is set in Status 9 (Completed).

Group

Displays the name of Group work order operations (GWOO). Click the View icon to open the Group work order operation (GWOO) application where the user can assign, add and run groups of Work order operations (WOO).

Read more about the Group work order operations (GWOO) here.

Ready at

Earliest date and time for starting the Work order operation (WOO).

Production tasks

The Production tasks column displays all production tasks linked to the Work order operation (WOO). Each task is represented by an icon. These icons can be clicked to open the Task details (TASK) application to view and edit details. Note that all icons will also display the title. The user must therefore click the icon, and not the text to open the Task details (TASK) application.

Production tasks icons - Status 1 - To do

- Status 1 - To do - Status 4 - In progress

- Status 4 - In progress - Status 5 - In review

- Status 5 - In review - Status 7 - Rejected

- Status 7 - Rejected - Status 8 - Done

- Status 8 - Done - Status 9 - Archived

- Status 9 - Archived

Active and Detached production tasks

The Production tasks tab includes two standard filters. Note that detached production tasks will be listed, but with strike-through if the Standard filter, Detached tasks is selected. In example: "Detached task".

Active tasks - Displays all active production tasks in the Task process (TSP)

Detached tasks - Displays all production tasks which for various reasons are no longer attached to the Task process (TSP).

When are production tasks potentially detached from a Production work order (PWO)?Changes to the Production structure (KITDOC)

Production work order (PWO) is cancelled

Production work order (PWO) is scrapped

Note

The space in the Production tasks column is limited. Therefore only a limited number of tasks can be displayed, meaning others can be hidden.

Pre-production tasks

The Pre-production tasks column displays all pre-production tasks linked to the Work order operation (WOO). Each task is represented by an icon. These icons can be clicked to open the Task details (TASK) application to view and edit details.

Pre-production tasks icons - Status 1 - To do

- Status 1 - To do - Status 4 - In progress

- Status 4 - In progress - Status 5 - In review

- Status 5 - In review - Status 7 - Rejected

- Status 7 - Rejected - Status 8 - Done

- Status 8 - Done - Status 9 - Archived

- Status 9 - Archived

To view all pre-production tasks in a related popup, click the Show all production tasks icon.

Note

The space in the Pre-production tasks column is limited. Therefore only a limited number of tasks can be displayed, meaning others can be hidden.

Scheduled production tasks

To view all tasks categorized by Production task, Pre-production task and Scheduled production tasks, click the Show all production tasks icon.

Show all production tasks icon.

The accompanied number states the number of scheduled production tasks linked to the Work order operation (WOO).

Click the Production status info icon to open the Planned operations for production work order (PWOPLO) application where the user can inspect and change Planned operations for the Production work order (PWO).

Read more here about the Planned operations for production work order (PWOPLO) here.

Click the Confirm picking icon to open the Pick (PICK) application where the user can initialize picking and perform the intended picking of parts and products.

Click the Scan picking icon to open the Picking with hand held terminals (SCANPICK) application where the user can efficiently pick parts and products by using hand held terminals.

Read more about Picking with hand held terminals (SCANPICK) here.

Click the Assign resource icon to open the Assign production resource (ASSIGNRES) application where the user can assign group members and alternative resource to the Work order operation (WOO).

Click the Arrow icon to open the Work order operation (WOO) application on the selected Work order operation (WOO).

Read more about the Work order operation (WOO) application here.

Context menu options

Options | Description |

|---|---|

View capacity and load | Click the View capacity and load option to open the Production resource capacity and load overview (RCL) application. All Production resources (RESCONFIG), belonging to the selected Production resource category (REC), will be visualized in an overview where the user can inspect the resource load in a specific period of time. Read more about the Production resource capacity and load (RCL) application here. NoteWhen entering the Production resource capacity and load overview (RCL) application from the List of work order operations for production resource category (RECWOO) application, the option to Include subcategories will be available as a checkbox in the header. |