Auto create Production work orders (PWO) for sub Product structures (KITART) and/or Production structures (KITDOC)

Context

Whether making to order, making to stock or assembling to order, creating a product can also require the production of the parts which make up the final product.

A produced product includes a Bill of Materials, which is often referred to as a BOM for short. In RamBase a BOM is stored as a Product (ART) of type or class KA or K, and these products are referred to as KITs.

When a Production work order (PWO) is created, the Product structure (KITART) is copied to a Production structure (KITDOC). This allows for a flexible production while maintaining the integrity of the intial BOM.

About KITART and KITDOC

Product structure (KITART) - Is accessed via the Product (ART) application and the active version is the current BOM for the product. It can be updated by creating new versions or revisions. When creating a new version, planned Production work orders (PWO) in Status 1-4 (and Status 5, if pick is not initiated and no time has been logged) can be updated with the new version, if changes are made.

Production structure (KITDOC) - Is accessed via the Production work order (PWO) application and is the flexible structure copied from the Product structure (KITART). Changes to a Production structure (KITDOC) will not reflect back on the Product structure (KITART), unless a new version is copied from the Production structure (KITDOC) to the Product structure (KITART).

This is relevant if the product is customer specific by creating a special structure for the Sales order item (COAITEM).

Complex Product structures (KITART), products of type KA, are often made up of other product structures, products of type K, which again can potentially require other product structures of type K. In other words, some kits might require sub kits, which also can require their own sub kits.

To simplify we can differentiate between the relative kits by calling them top level kits and sub kits.

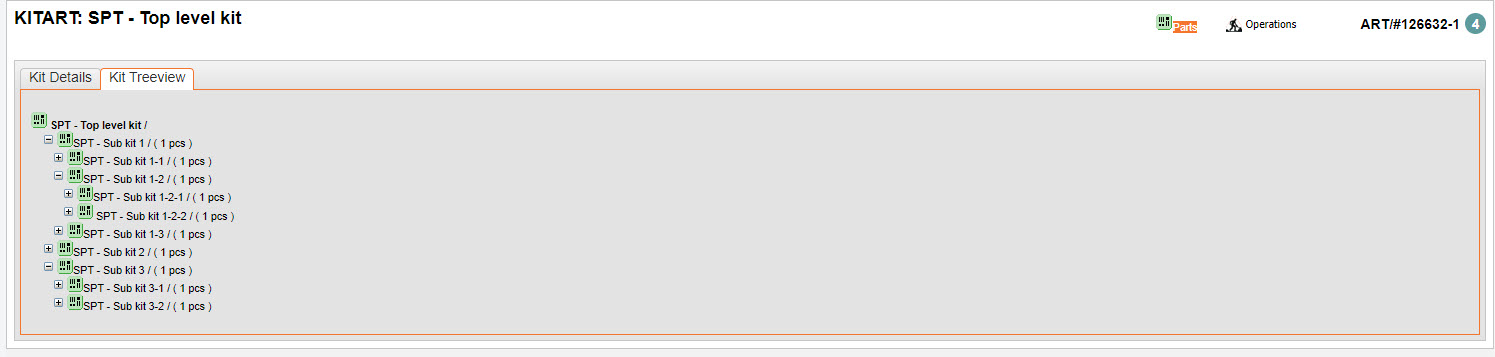

Take a look at the example below from the Product structure (KITART) application:

Figure 1. Example of a top level kit with sub kits

View from the KITART application, opened via the Product (ART) application, Structure button > Kit Treeview tab.

Top level kit

Sub kit 1

Sub kit 1-1

Sub kit 1-2

Sub kit 1-2-1

Sub kit 1-2-2

Sub kit 1-3

Sub kit 2

Sub kit 3

Sub kit 3-1

Sub kit 3-2

Important

If there is a need for sub kits, Production work orders (PWO) for these can be automatically created. But only if the auto create functionality is configured to do so.

Setup

As visualized in figure 1 and 2, creating and completing a Production work order (PWO) for the top level kit will require a total of ten sub kits on various levels.

Production work orders (POW) for these sub kits can be created manually, as a production need will be created, but to save time and planning they can be automatically created.

Activate a company setting to auto create Production work orders (PWO) for all sub kits.

If this is activated, it is useful to verify that activating the setting also activates the checkboxes for auto create in Product (ART) and Product structure (KITART)/Production structure (KITDOC).

Note that if it is only activated in the Production structure (KITDOC), unless it is copied as new version to the Product structure (KITDOC), enabling the checkbox will only apply to that Production work order's (PWO) auto created sub kits.

Activate on all levels

The auto create functionality only applies one level down. Therefore the auto create functionality must be enabled on every level that has sub kits. If not, Production work orders (PWO) will not be created for lower sub kit levels.

Activate a company setting to auto create Production work orders (PWO) for sub kits

The Company setting (CSV), Default create value for products - Auto create workorder can be set to Yes to simplify the procedure.

Using the example, figure 2 - the simplification of kit levels, as visualized above:

If the setting is on and a Production work order (PWO) is created for the top level kit, Production work orders (PWO) will only be created for the first sub level, in this example sub kit 1, sub kit 2 and sub kit 3. The setting does not apply to the second sub level, in our example sub kit 1-1, sub kit 1-2, sub kit 3-1 and sub kit 3-2 and so on.

To create Production work orders (PWO) for the total potential sub kits, follow the procedures listed in the section below.

In Product (ART), define or verify Production work orders (PWO) are also created for sub kits

To automatically create Production work orders (PWO) for sub structures, open the Product (ART) application and enable the Auto create work orders for sub structures checkbox.

Open the Product (ART) application from the RamBase menu by selecting Product followed by Structures management and finally Product structures.

This will open the Product (ART) application pre-filtered on products containing structures, as the Auto create work orders for sub structures checkbox is only available for those products.

Select or search for the product in the left list in the Product (ART) application.

To enable the Auto create work orders for sub structures checkbox, click the Properties tab followed by the Production sub-tab.

Click the Auto create work orders for sub structures checkbox to either enable or disable the feature.

Repeat steps 2-4 for all sub kits, and their sub kits.

In Product structure (KITART) or Production structure (KITDOC), define or verify that Production work orders (PWO) are also created for sub kits

Open the Product (ART) application from the RamBase menu by selecting Product followed by Structures management and finally Product structures.

This will open the Product (ART) application pre-filtered on products containing structures.

Select or search for the top level kit in the left list in the Product (ART) application.

Click the Structure button to open the Product structure (KITART) application.

Click the Kit details tab.

Locate, and then select the product structures of class K or KA by clicking the line, highlighting it.

Double left click or press ENTER to open the Structure part item (KITARTITM) application.

In the Parameters area, enable the AutoCreateSubProduction checkbox, or verify that it is.

Repeat steps 5-6 for all sub kits, and their sub kits.

Tip

Navigation to the Production structure (KITDOC) is based on the users role and context. This example will use the Production work orders (PWO) as the starting point as it lists all Production work orders (PWO), independent of status.

A Production structure (KITDOC) is only created when a Production work order (PWO) for the Product structure (KITART) is created.

Open the Production work orders (PWO) application from the RamBase menu by selecting Production followed by Production again and finally Production work orders.

Select or search for the top level Production work order (PWO).

To open the Production work order (PWO) applicaiton, select it and press ENTER or click the Right arrow icon.

In the Links area, click the Structure button to open the Production structure (KITDOC) application.

Click the Kit details tab.

Locate, and then select the product structures of class K or KA by clicking the line, highlighting it.

Double left click or press ENTER to open the PWO Structure part item (KITDOCARTITM) application.

In the Parameters area, enable the AutoCreateSubProduction checkbox, or verify that it is.

Repeat steps 5-6 for all sub kits, and their sub kits.

Checklist

Use this checklist if the functionality does not give the expected result.

Activate the Company settings (CSV), Default create value for products - Auto create workorder

Activate the Auto create work orders for sub structures checkbox in the Product (ART) application

Activate the AutoCreateSubProduction checkbox in the Product structure (KITART) or the Production structure (KITDOC) application