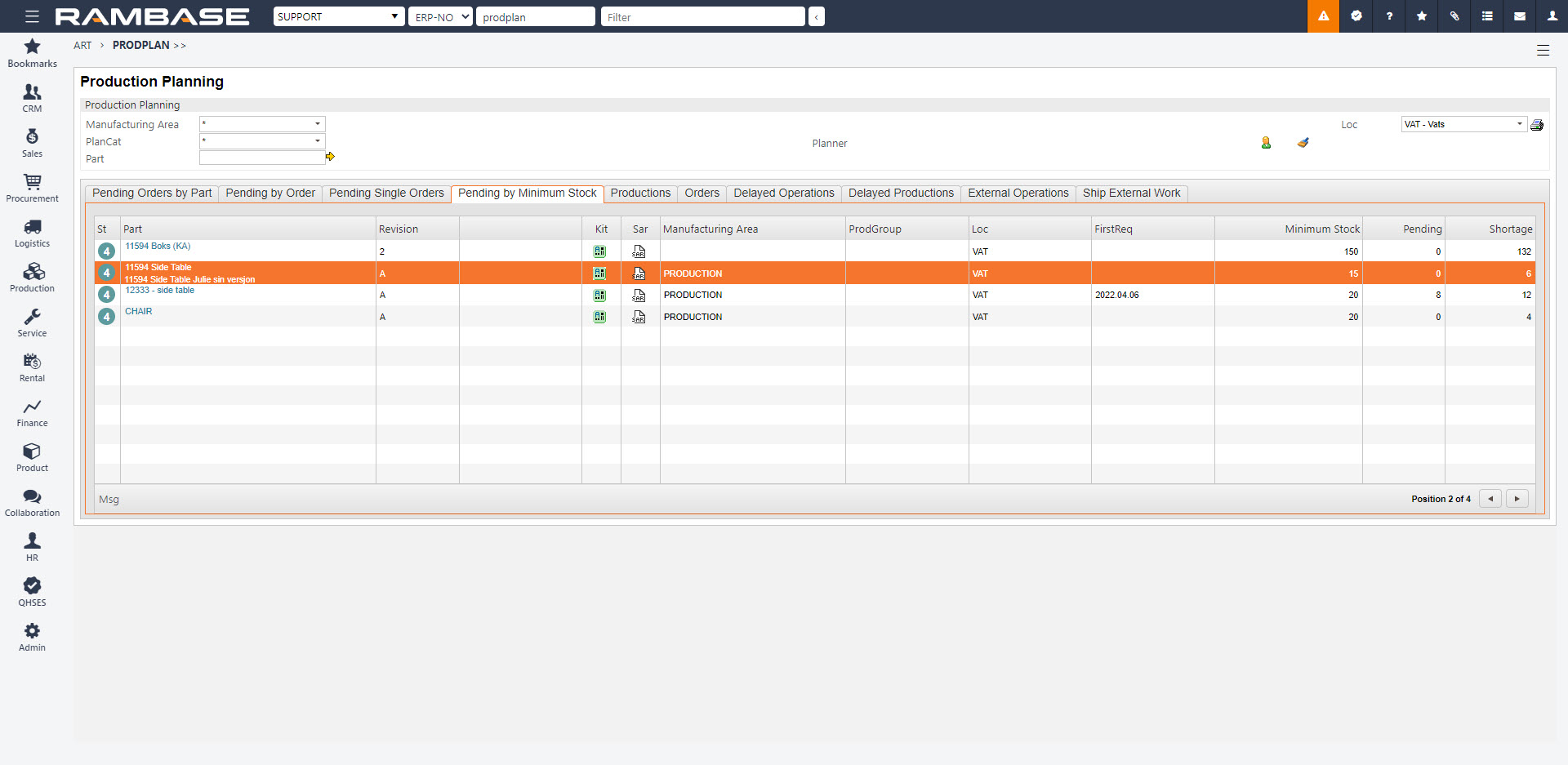

Pending by minimum stock

From the Production planning (PRODPLAN) application, the Pending by minimum stock tab gives the required minimum stock of the product required for daily operations.

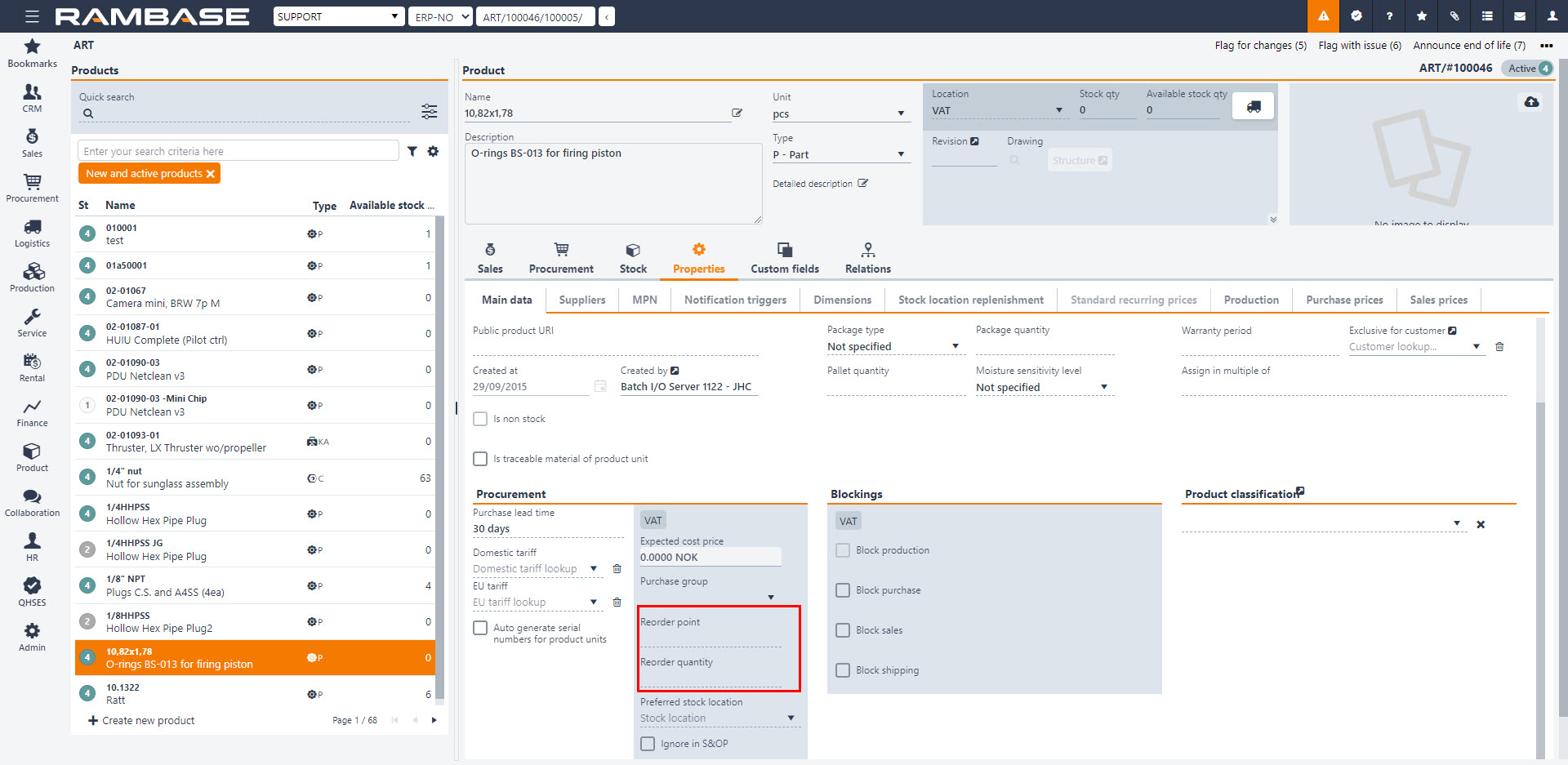

Setting the minimum stock via Product (ART) application

The minimum stock is set on the product representing the material or part. To open the Product (ART) application, select Product, then Product management and finally Products in the RamBase menu. The Stock tab details the current stock and the quantity available for use.

In Properties, select the Main data tab. Navigate to the Procurement area. Enter the desired value in the Reorder point field.

The Pending by Minimum Stock tab in the Production planning (PRODPLAN) application lists the products where there is a shortage. Only products with a specified minimum quantity are shown here.

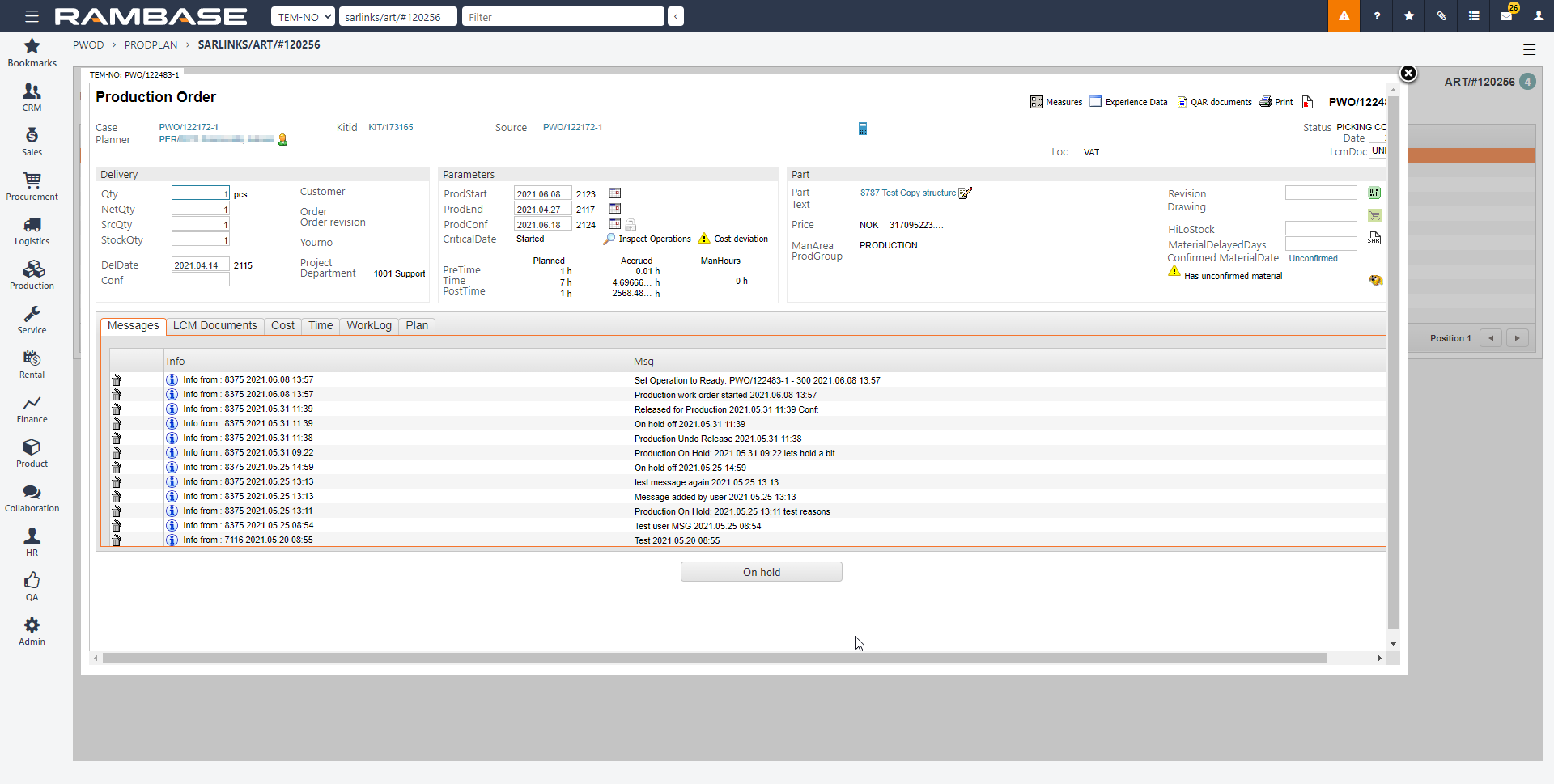

Press ENTER on the selected line to open the Production work order (PWO) application. The quantity shown in the Qty field, in the Production work order (PWO) application, is comprised of the minimum stock quantity. This field is editable, and can be updated according to the Reorder point given for the selected product from the Product (ART).

If the Create Production button is clicked, the entry in Pending Minimum Stock is not displayed from the Production planning (PRODPLAN) application.

Note

If there are active production work orders to complete in the future, for products with a specified shortage quantity, the free quantity is affected by this in the way that the future productions fill the current shortage. If you have shortage, but RamBase does not show a purchase requirement in the Purchase (PUR) application, check if there are any production orders that make up for the shortage in the future.