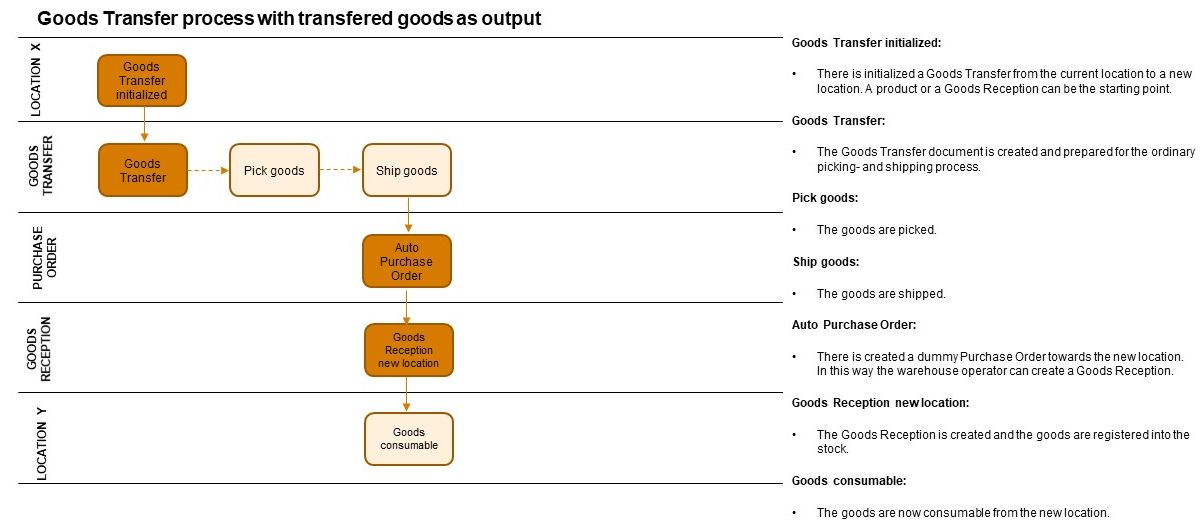

Goods transfer

A goods transfer process can be defined as the process where stock is transferred from one warehouse to another.

Output from the goods transfer process

Goods moved from one warehouse to another, but the financial stock value will not be changed during the process.

Structured products transferred from one warehouse to another, will be treated by the system as they are purchased and not manufactured inhouse.

If a company has several warehouse locations spread over several geographical locations, there will most likely be regular logistical transactions between these. It is normal in distribution to have one central warehouse where the goods can be distributed between several smaller warehouses strategically located near large key customers. No matter which model the company uses, the need for sending goods between warehouse locations will be apparent.

When "Allow goods transfer to this location" is flagged on a Location (LOC), the system will generate a Supplier (SUP) with the same name as the Location (LOC). This will be an internal supplier to be used when transferring goods from one location to another. If one should remove the flag on the location, the supplier will be closed to Status 9. The Supplier (SUP) created will have Supplier Classification: S. The specific suppliers for this can be found using the following restriction: SUP;ACCOUNTCL:S

Tasks involved in this process

Create goods transfer

The need for stock transfer must be created and registered.

Ship goods

The goods need to be prepared and shipped from the warehouse.

Register reception

Goods reception at the receiving warehouse has to be done.