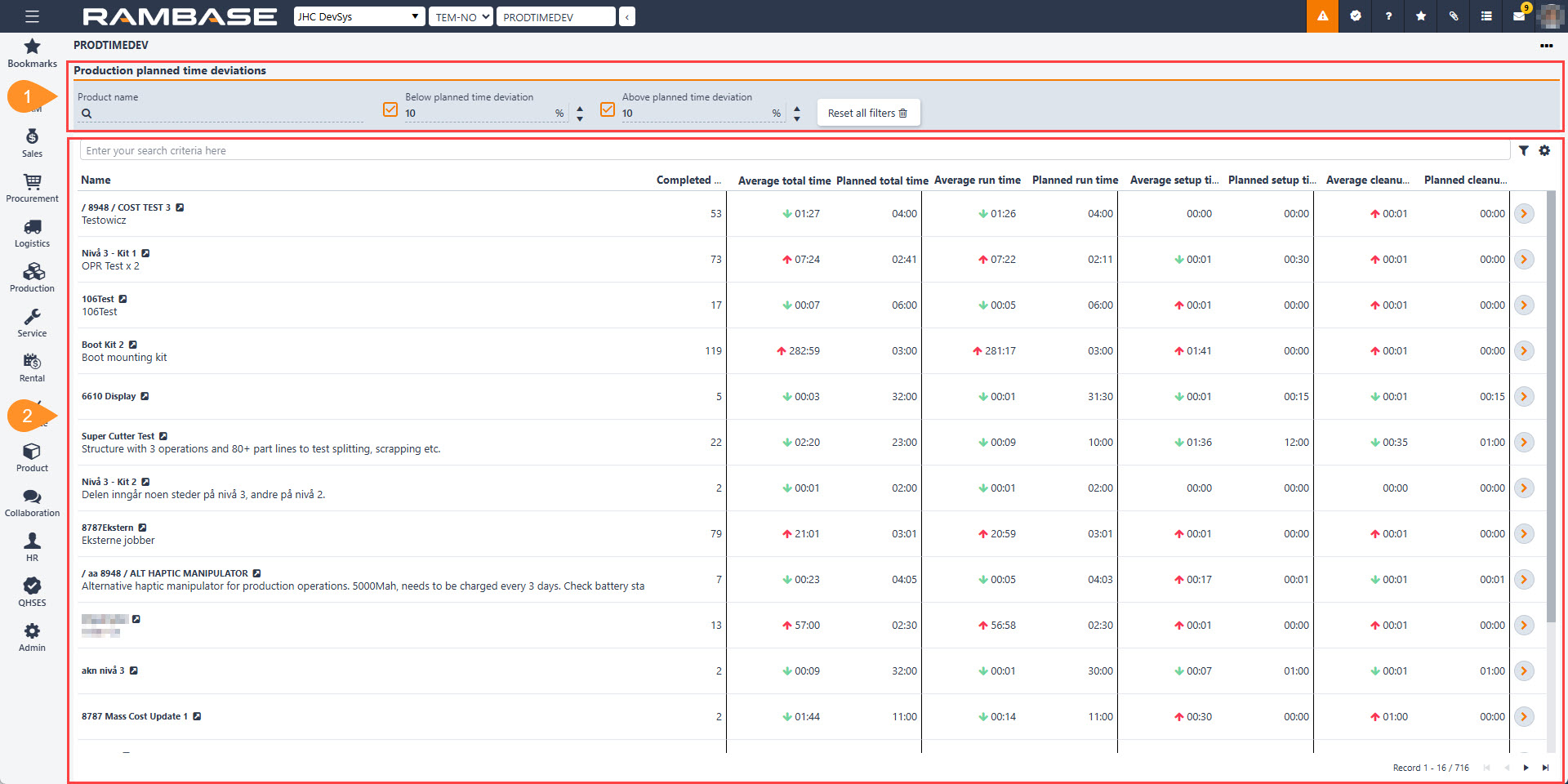

Production planned time deviations (PRODTIMEDEV)

The Product structure planned time deviations (PRODTIMEDEV) application works in unison with the Update product structure operation planned times (PRODTIMEUPDATE) application.

Application synergy

Product structure planned time deviations (PRODTIMEDEV) application - Identify deviations in total planned time of all Operations (OPR) and the average production time for Product structures (KIT).

Update product structure operation planned times (PRODTIMEUPDATE) application - View all Operations (OPR) for a selected Product (ART) with a structure. Adjust the planned time for Operations (OPR) based on the deviations, specified by the user.

Navigate to the application

Option 1: Click the Program field and type "PRODTIMEDEV" and press ENTER.

Click here to read more about the user interface.

Situation: Deviations in planned and average production time has been found in the Product structure planned time deviations (PRODTIMEDEV) application. The planner opens the Update product structure operation planned times (PRODTIMEUPDATE) application to inspect the deviations and adjust accordingly.

Selects product.

Uses the fields in the header to adjust the deviation scope.

Identifies red arrows for Operations (OPR) with longer duration than the planned time, and green arrows for Operations (OPR) with shorter duration than the planned time.

Selects the appropriate action in the Actions column:

Edit product structure operation to manually adjust planned times.

Set product structure operation times to average.

Updates the structure which contains the Operations (OPR) with the Update structure button.

Overview

The application contains a header and a list. The user provides varaibles in the header to define deviations in the list.

Header

The header is used for defining deviations in planned time for all Operations (OPR) and the average production time for Product structures (KIT). The user can filter the list on a product name and the list will display Products (ART) with a Product structure (KITART) of type/class K, KA, KS or KM. These Products structures (KITART) contains Operations (OPR). The Operations' (OPR) setup, run and cleanup time is then displayed in the columns of the list. Based on the user defined deviations, these will be noted by green or red arrows.

Product name search field - To filter on Product names (ART), type a value and the list will be filtered on product names which contains the provided value.

Below planned time deviation field, checkbox and Arrow icon - Define a deviation (Red arrow icon or Green arrow icon) in planned and average time by deciding the below planned time percentage.

Example with a value set at 10%: If the average time is 10% or greater than the planned time for Planned run time , Planned setup time or Planned cleanup time a green arrow will be displayed. As this will indicate that the average time used is 10% or below the planned time.

Default value is 10%

Changes to this field will be reverted back to the default value, if navigating from the application.

To enable or disable the filtering function of the Below planned time deviation field.

Increase or decrease the percentage value by one (1), by clicking the Arrow icons.

Above planned time deviation field, checkbox and Arrow icon - Define a deviation to display a Red arrow icon in planned and average time by deciding the above planned time percentage.

Example with a value set at 10%: If the average time is 10% or greater than the planned time for Planned run time, Planned setup time or Planned cleanup time, a Red arrow icon will be displayed. As this will indicate that the average time used is 10% or greater than the planned time.

Default value is 10%

Changes to this field will be reverted back to the default value, if navigating from the application.

To enable or disable the filtering function of the Above planned time deviation field.

Increase or decrease the percentage value by one (1), by clicking the Arrow icons.

Reset all filters button - To reset the changes made to the header, click the Reset all filters button.

List

When deviations have been defined in the Header area, planned time for all Operations (OPR) and the average production time for Product structures (KIT) will be listed by Product (ART). The list will display Products (ART) with a Product structure (KITART) of type/class K, KA, KS or KM. These Products structures (KITART) contains Operations (OPR). The Operations' (OPR) setup, run and cleanup time is then displayed in the columns of the list. Based on the user defined deviations, these will be noted by green or red arrows.

The user can further filter the list by using the Search field, the Filter builder and decide which information is displayed by enabling or disabling columns in the Column settings.

Search field - Click the Search field and then press SPACEBAR. This will list all of the available fields to filter the list on. Either select the intended filter or use the UP and DOWN arrow keyboard keys to navigate to the necessary filter and press the ENTER key to apply the filter. A popup will appear with filter query expressions. The expressions can be inspected here.

Once you select the expression another popup will follow where you can decide which operator option to use. There is an And, Or and OrderBy operator option available which enables you to add another field to the filter. When finished building your filter query, press the ENTER key and the filtered result is displayed in the list.

Filter builder icon - Click the Filter builder icon to open a popup where the user can select filters from the Standard filters area. Selected filters will be visible below the Search field. Active filters are marked orange, inactive are marked gray. The user can also Create custom filters by selecting Field, Operator and Value in the Create custom filters area, and then pressing the Save filter button. Saved filters will be available from the My saved filters area. Click the saved filter to add it below the Search field.

Column settings icon - To select the information displayed, click on the Column settings icon and hover over Columns. Then select the intended columns. The selection of data can be exported to Excel via the Export to excel option in the Column settings. The Reset to default view is also useful in resetting column width and placement. A description of the columns are listed in the table below.

Column | Icons | Descriptions |

|---|---|---|

Name | ' | Displays the name and description of the Product (ART). The product contains a Product structure (KITART) of type/class K, KA, KS or KM. To open the Product (ART) application, and view and edit details of the product, click the View icon. |

Completed work orders | Displays the number of completed Production work orders (PWO) for the listed Product (ART). | |

Average total time | Displays the sum of the values in the columns; Average run time, Average setup time and Average cleanup time. | |

Planned total time | Displays the sum of the values in the columns; Planned run time, Planned setup time and Planned cleanup time. The individual values are defined when setting up the Operation (OPR), in the Processing area in the Operation (OPR) application. | |

Average run time | Displays the average run time for all completed Work order operations (WOO) for a single Production work order (PWO). | |

Deviation run time | Displays the deviation between the Planned run time and the Average run time in percent. | |

Shortest run time | Displays the shortest run time for all completed Work order operations (WOO) for a single Production work order (PWO). | |

Longest run time | Displays the longest run time for all completed Work order operations (WOO) for a single Production work order (PWO). | |

Planned run time | Displays the planned run time for all completed Work order operations (WOO) for a single Production work order (PWO), displayed in the HH:MM format. Note that in the Operation (OPR) application, the Planned run time is setup in decimal hours HH.MM. | |

Average setup time | Displays the average setup time for all completed Work order operations (WOO) for a single Production work order (PWO). | |

Deviation setup time | Displays the deviation between Planned setup time and Average setup time, in percent. | |

Shortest setup time | Displays the shortest setup time for all completed Work order operations (WOO) for a single Production work order (PWO). | |

Longest setup time | Displays the longest setup time for all completed Work order operations (WOO) for a single Production work order (PWO). | |

Planned setup time | Displays the planned setup time for all completed Work order operations (WOO) for a single Production work order (PWO), displayed in the HH:MM format. Note in the Operation (OPR) application, the Planned setup time is defined in decimal hours HH.MM. | |

Average cleanup time | Displays the average cleanup time for all completed Work order operations (WOO) for a single Production work order (PWO). | |

Deviation cleanup time | Displays the deviation between Planned cleanup time and Average cleanup time, in percent. | |

Shortest cleanup time | Displays the shortest cleanup time for all completed Work order operations (WOO) for a single Production work order (PWO). | |

Longest cleanup time | Displays the longest cleanup time for all completed Work order operations (WOO) for a single Production work order (PWO). | |

Planned cleanup time | Displays the planned cleanup time for all completed Work order operations (WOO) for a single Production work order (PWO), displayed in the HH:MM format. Note in the Operation (OPR) application, the Planned setup time is defined in decimal hours HH.MM. | |

| To open the Update product structure operation planned times application, click the Right arrow icon. The application allow a view of all Operations (OPR) for a selected Product (ART) with a structure. Adjust the planned time for Operations (OPR) based on the deviations, specified by the user. |