Cost Deviation

When running a production you might face a cost deviation due to incorrect time usage assumptions in the planning phase. This will be the case if an operation, which is defined to take a certain amount of time, spend less or more than the estimate. Every operation has a price related to the time usage, and this is calculated by how long the operation actually takes.

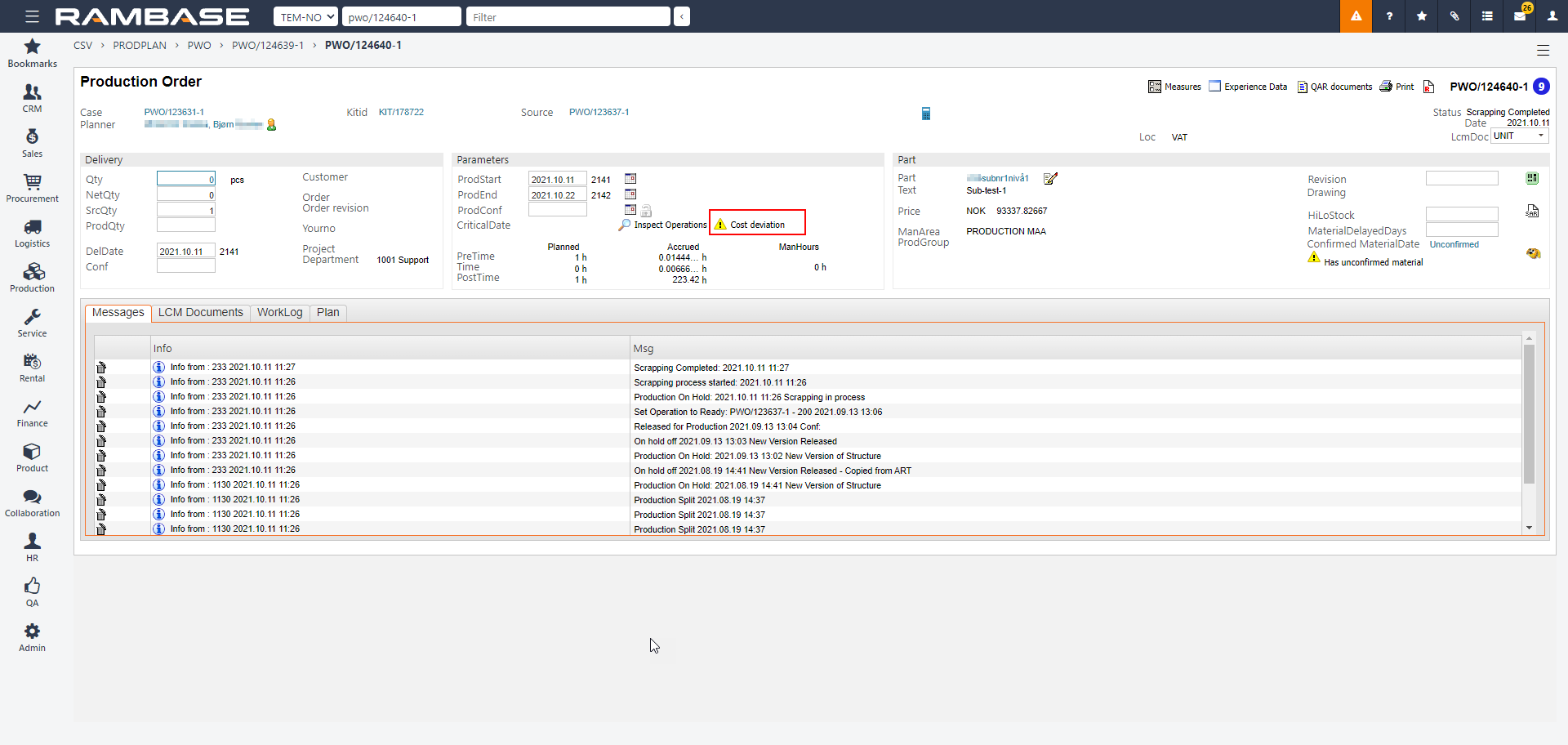

Cost deviations are flagged in the Production Work Order (PWO) by a yellow warning icon at the top left called Cost deviation.

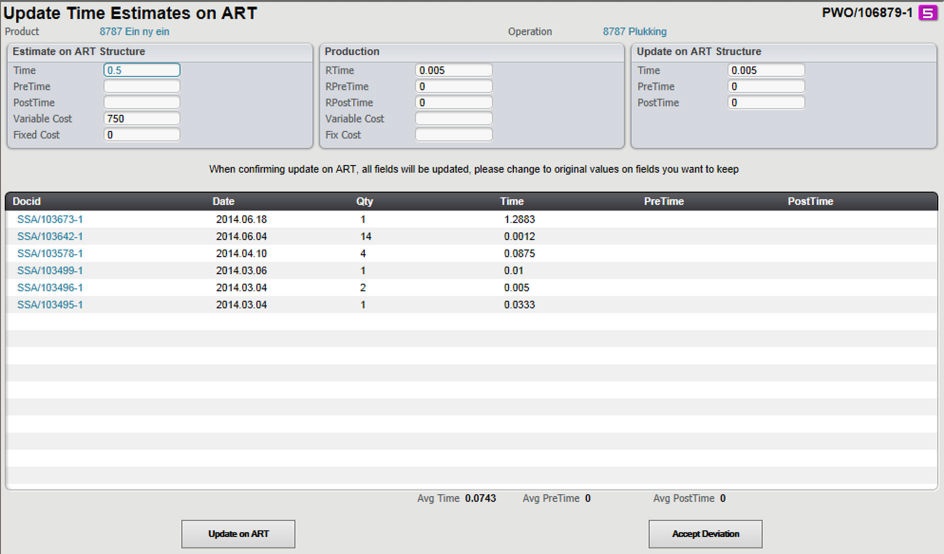

There are two methods of handling a cost deviation, either by accepting the deviation or by updating the structure in the article archive to better estimate time usage in future productions.

Click the Cost deviation icon to view the deviation in question.

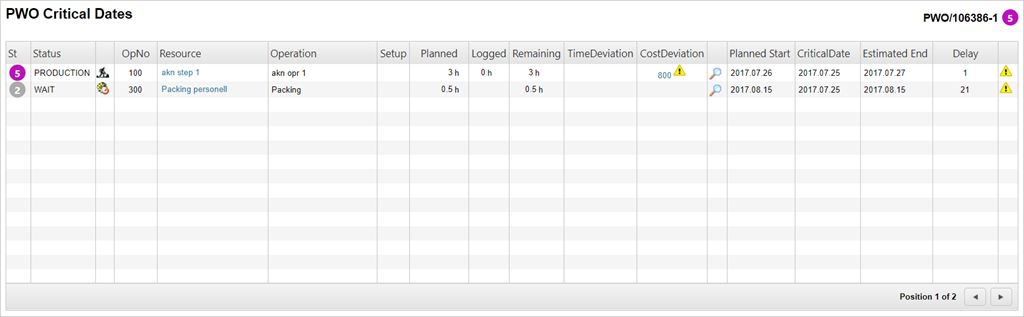

Click the warning icon on the operation containing the deviation to perform an action.

Here you may either update the structure or accept the deviation using the buttons at the bottom. Use the history seen in the item lines to get a better estimate for future productions.