External work - Operation handling and logistics

An external work order operation is an operation done by a supplier to a product in the Production work order (PWO). The product is sent to a supplier for this operation or the supplier runs the operation at your own site (in house external operation). This implies that an external operation includes processes for purchase, outbound logistics and inbound logistics.

Changes to the procurement and logistics process

We have made some changes to the procurement and logistics processes.

The main changes are:

The serial numbers are not copied to the Purchase order (SPO), therefore, there are no serial number requirements for any step in the purchase and logistics processes.

Full flexibility to do partial shipments to the supplier. The shipments are not connected to the Sales order responses (SOA) items if they exist, only to the original SPO.

The sections below describe the applications that are used for handling the external operations and the processing of these operations based on the implemented changes.

Procurement processes: purchase order, order response

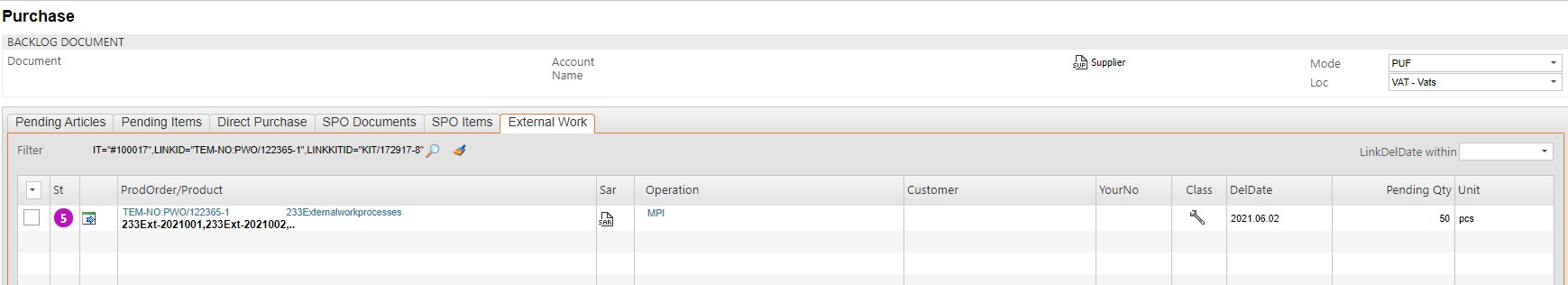

The Purchase (PUR) application has a tab for creating Purchase orders (SPO) for external work.

It is pre-filtered for the work order and operation if accessed directly from the pending link in the assignment list in the PWO, but the tab also features filtering and a multi-selection tool for creating Purchase order (SPO) for multiple work orders.

The result is always one SPO item per combination of a specific work order (PWO) and operation number.

Order confirmation from supplier

The order confirmation from the supplier is handled by standard applications and methods. Transport the SPO item to a Supplier order response (SOA), and it can be split to several SOA items if the supplier confirms partial delivery of the ordered quantity. The same rule applies to the SOA items, one SOA item is only valid for the combination of a specific work order and operation number.

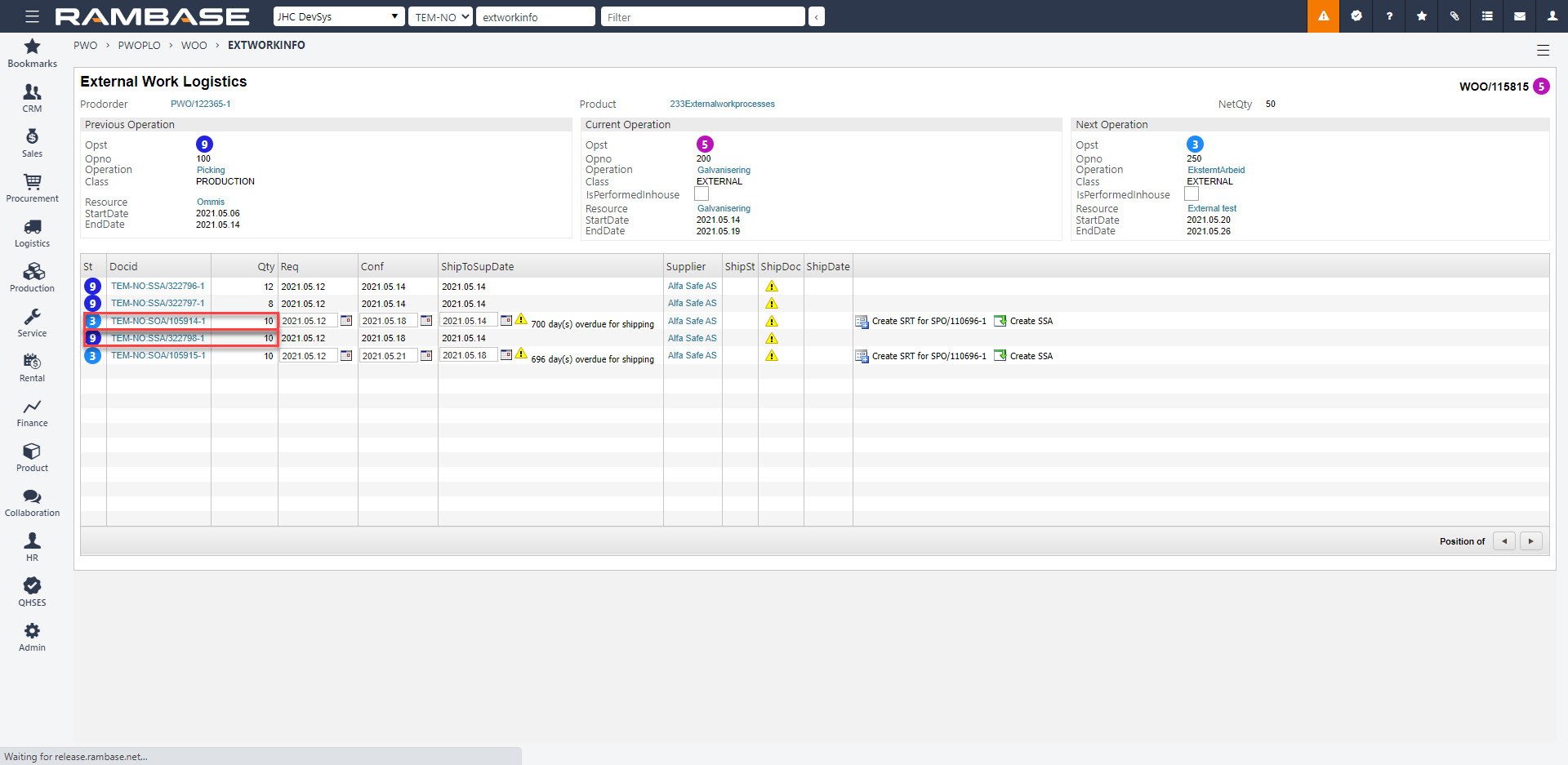

External work logistics overview

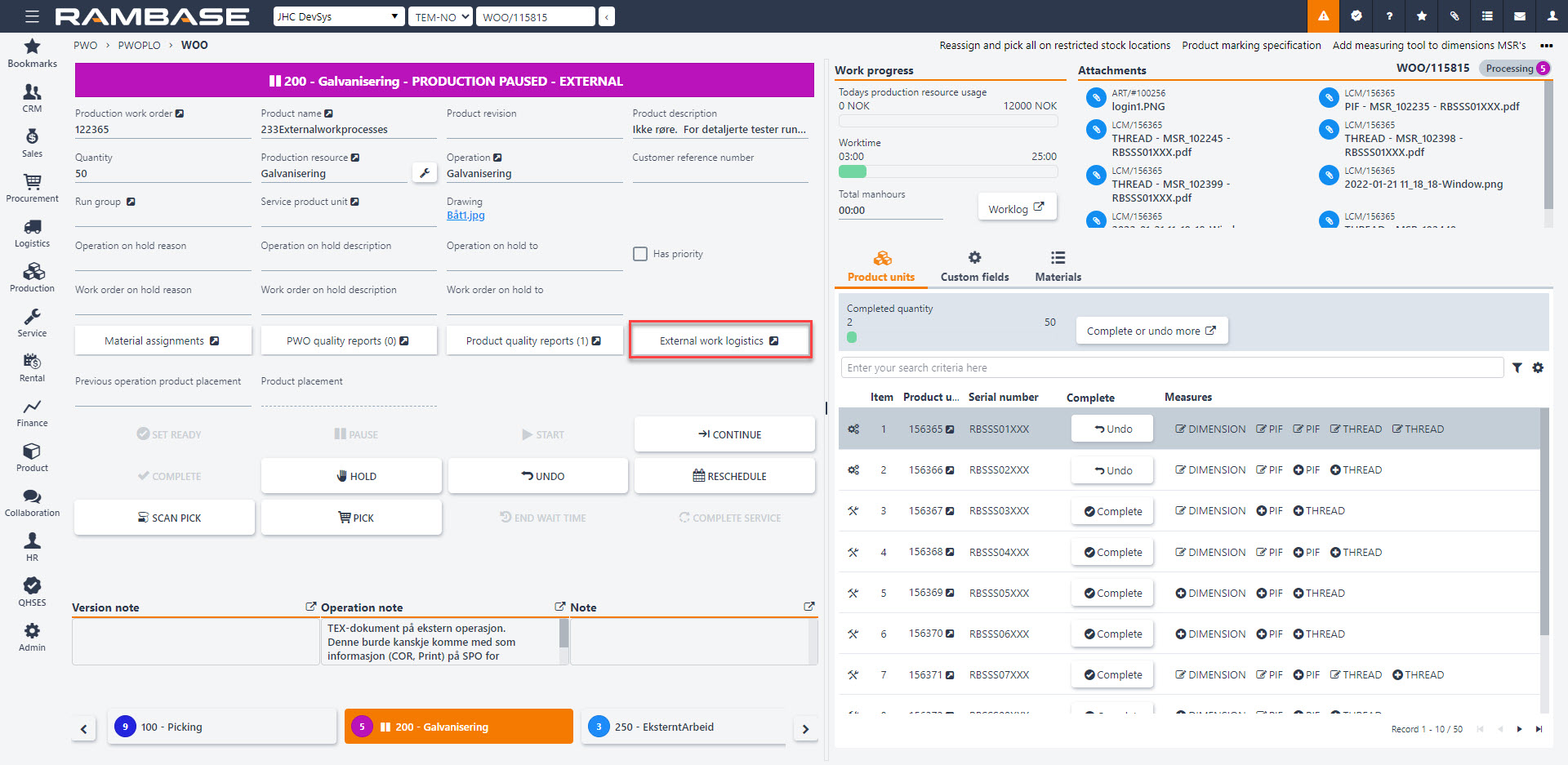

The Production work order (PWO) has no special link to the logistics view for external operations. The operations are purchased, confirmed and received and this is displayed as for the parts of the PWO BOM in the list of assignments to the PWO. The Work order operation (WOO) has a link to a view of the external work logistics:

The external work logistics application shows all the purchase and logistics details for the operation, the purchase orders, the shipments to the supplier, the received quantity and information about the previous and next operations and the scheduled dates for the operations.

The Product units received progress bar in the Product units tab shows the number of units collected from the suppliers of external operations. It is displayed only if the purchase order has been requested for the operation (work order is linked to a SPO in status 1 or higher). User may enter the External work logistics for the currently selected external operation (WOO) to see the status of the purchase orders (SPO). When product units are retrieved, the external work should be automatically completed and set to Status 9, while the subsequent, in-house operation (if it exists in the structure), should be automatically set as ready in Status 3.

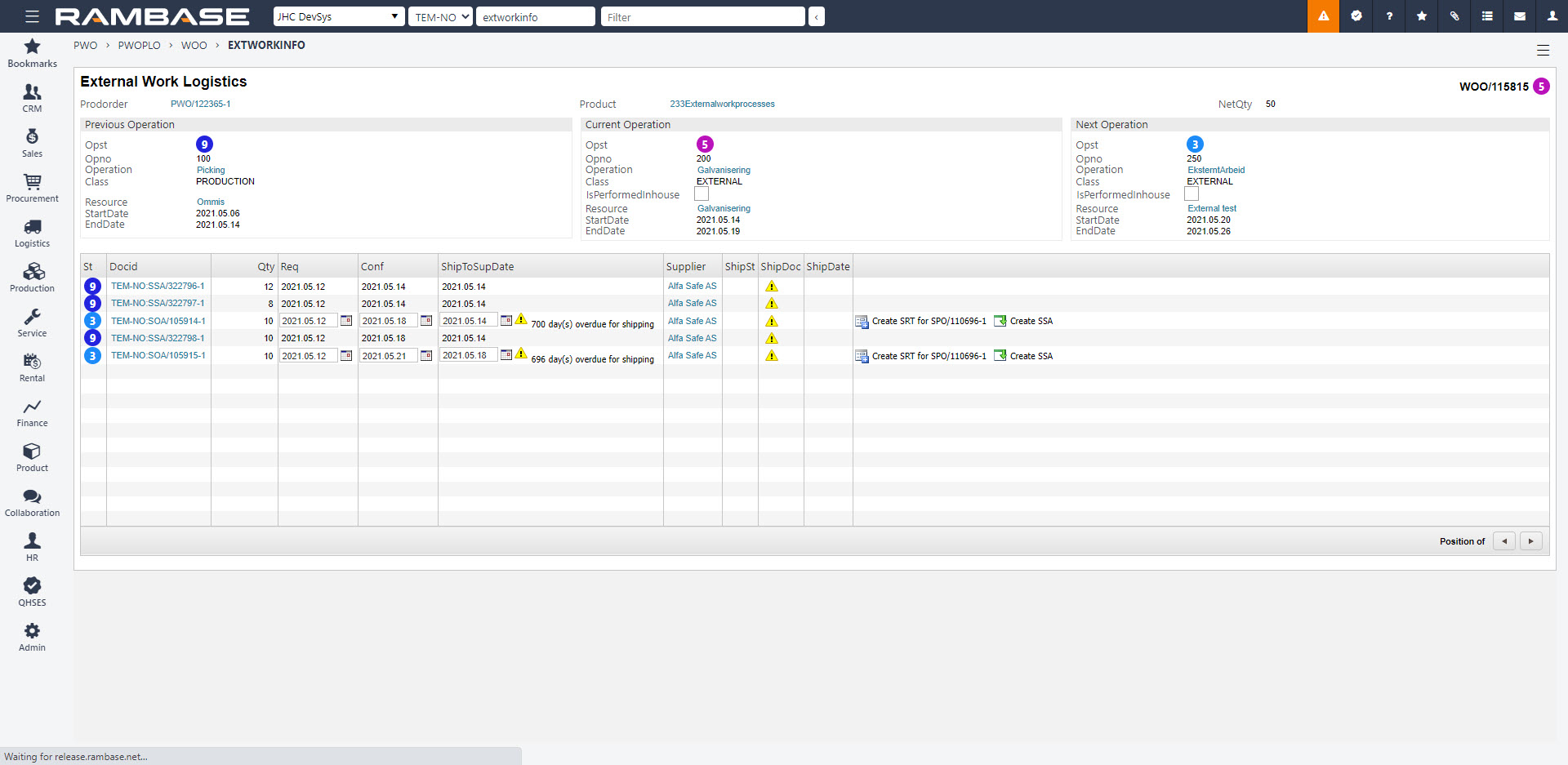

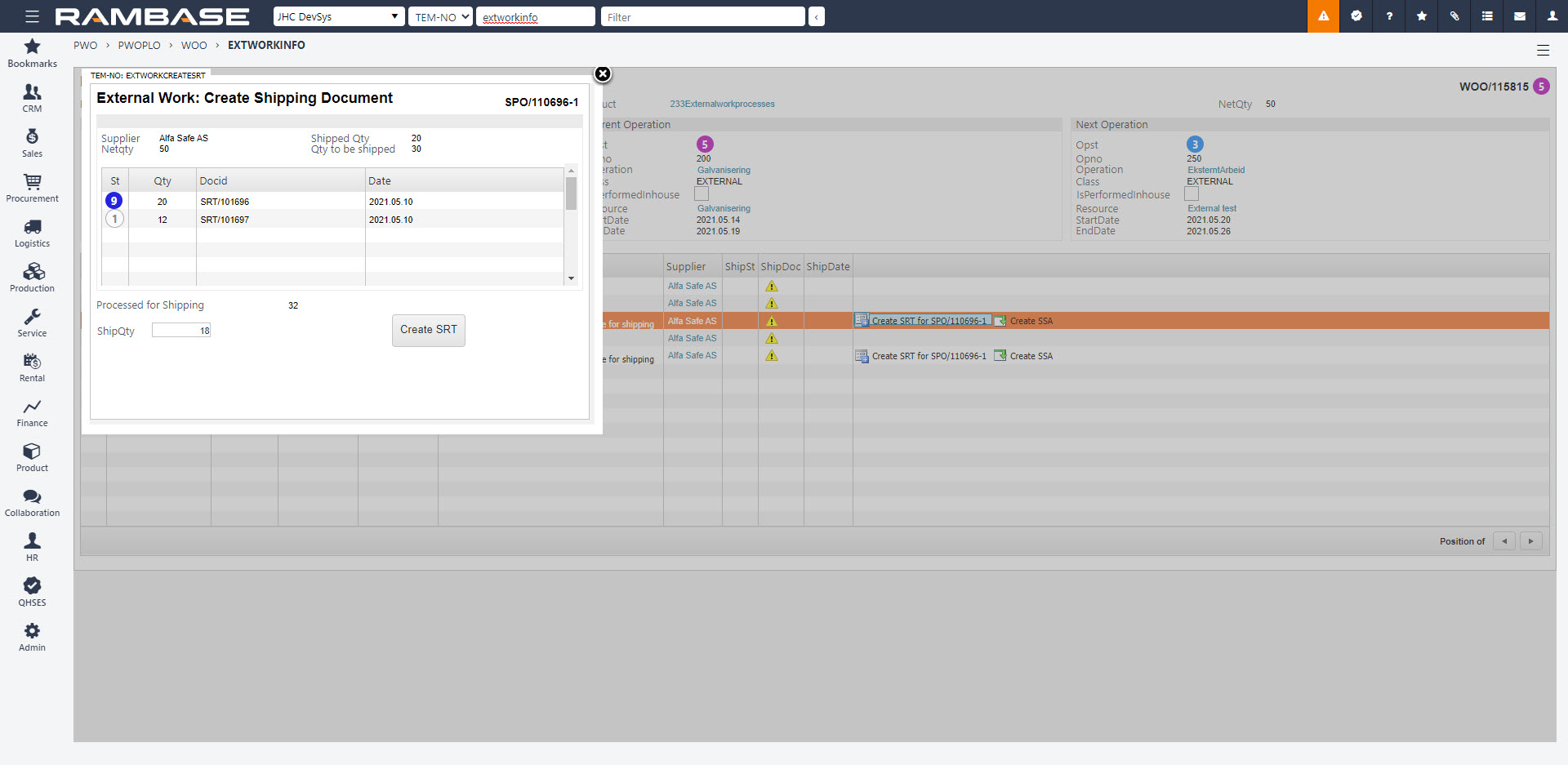

Create Supplier returns (SRT) for shipment to the supplier

It is not mandatory to create SRTs for shipment to the supplier. However, create SRT when the products are shipped by some means of transport and whenever there are partial shipments for external operations. There is no need to shipping products if the supplier is doing the operation in-house at your factory. The reference for the shipments is the Purchase order (SPO) for the operation, so even though the application shows multiple lines for creating SRT, there is only one total summary for shipments to the operation. The Create SRT button opens a popup to create SRT for the quantity to be shipped and where the reference to the shipments is shown.

Please note that the Create SRT option is displayed at each PO line for the operation, the shipment is not done to one specific SPO item or SOA item, the shipment has only reference to the SPO and the quantity to be shipped does not have to match the quantity of one specific SOA item.

Shipments where parts/material must be picked and shipped together with the products

Parts and material that shall be picked and shipped together with the products have to be added in the BOM (KIT) as material lines to the external operation. These parts are assigned to the Production work order (PWO), but are also added to the SRT as items to be shipped. But: The SRT items do not have any stock assignments, it is only a delivery note for the external operation. That means that the picking process is done on the PWO.

The picking is initiated when the first SRT is created for the operation, and technically because that starts the external operation, and starting the operation is the trigger for initiating picking.

Note:

The picking of these parts must be added as a routine when handling the shipment, and the picking process must be done from the PWO.

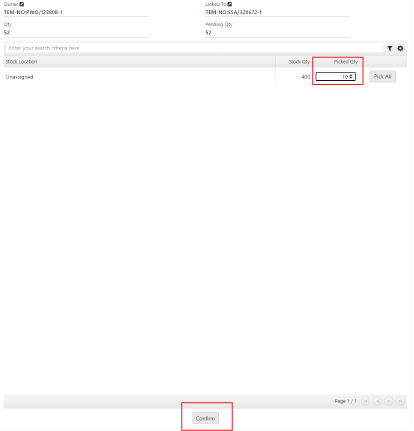

If there is a partial shipment for the external operation, the SRT items will have quantities of added parts that are matching the number of products to be shipped. But the picking is initiated for the full quantity (quantity linked to stock) and the user must reduce the picked quantity in the picking application. The balance will remain unpicked, but still initiated and locked for the next shipment where the user then must confirm more of the quantity as picked.

Change picked quantity and confirm:

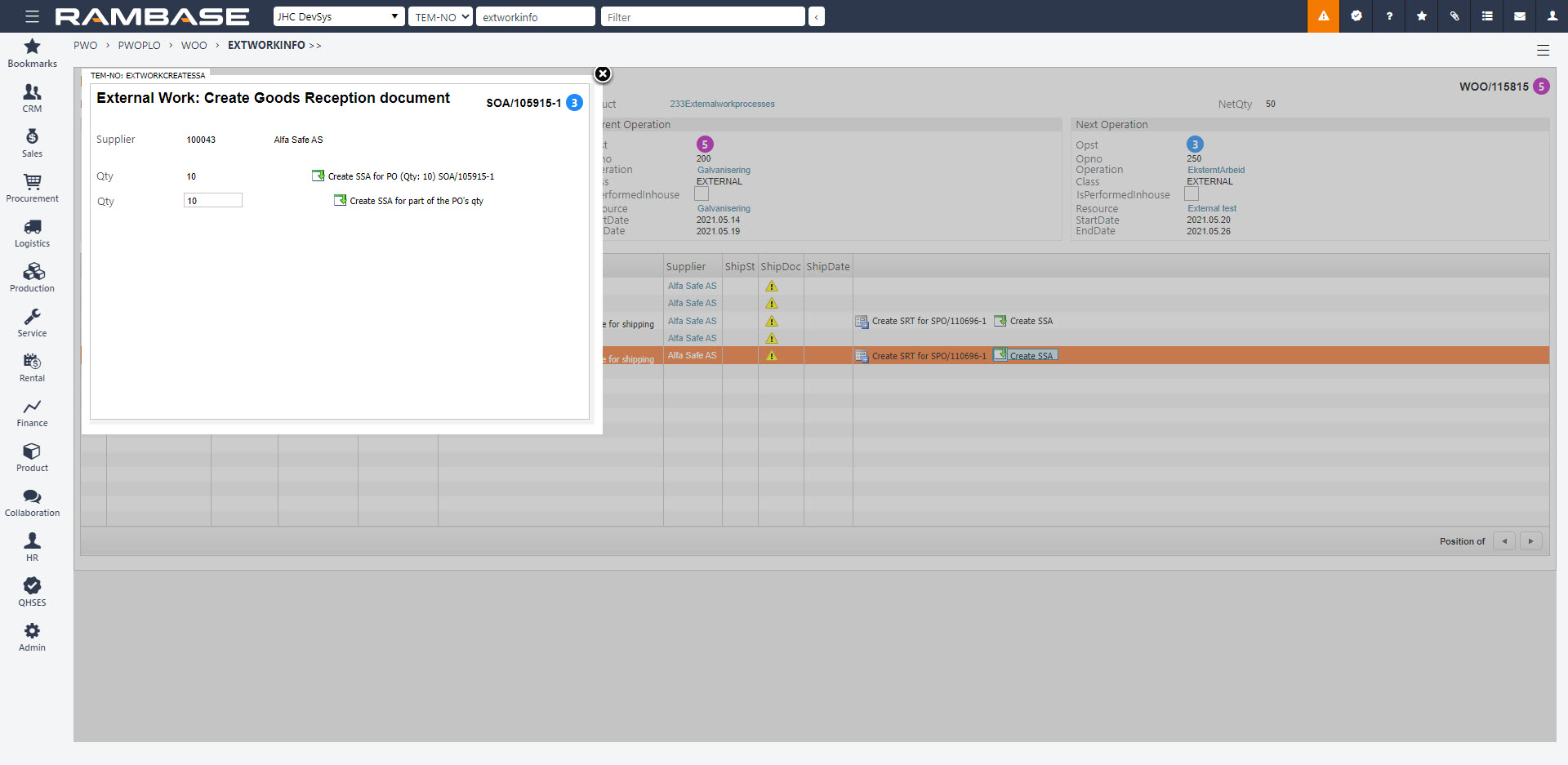

Receive products from external work – Create SSA

Products can be received from the supplier in any quantity, and the quantity does not necessarily have to be the full quantity from a specific PO item (SPO or SOA). But the reception is done from one of these items as they need so be closed (completely received) at some time before the operation can be completed. In the example below we have selected Create SSA at one SOA item with quantity = 10. This SOA item is then the reference in the create SSA popup and 20 is suggested as quantity to be received:

We reduce the quantity to receive 6 pcs, the popup is refreshed and available quantity to receive for this SOA item is now 4 pcs. Select the Esc key to go back to the overview and it will show the result of having received 6 pcs for the SOA item:

There is no option to receive in total a higher quantity than ordered for the external operation. The operation is automatically closed (done) when the last goods reception is done. There is also no option to, for example. receive 15 pcs and select that 10 pcs is from one SOA item and 5 pcs is from another SOA item/SPO item. The source of a SSA item is only one item, it can not come from two PO items. A more flexible selection method will be evaluated for next version, but the result will always be that one SSA item can only have one SOA/SPO item as source. But an SPO/SOA item can have several partly deliveries, several SSAs.

Complete the operation

The operation is automatically closed when the last products are received to stock.