Reorder point for a product in a specific stock location

The feature of having a Reorder point (required minimum stock level) for a product at a specific stock location is designed for cases where the replenishment should take place by ordinary move of goods between Stock locations (STL) within one Location (LOC). It is not designed for refill by goods transfer from other locations, nor by purchase of products.

Reorder quantity is the suggested replenishment quantity when the stock level has reached the Reorder point.

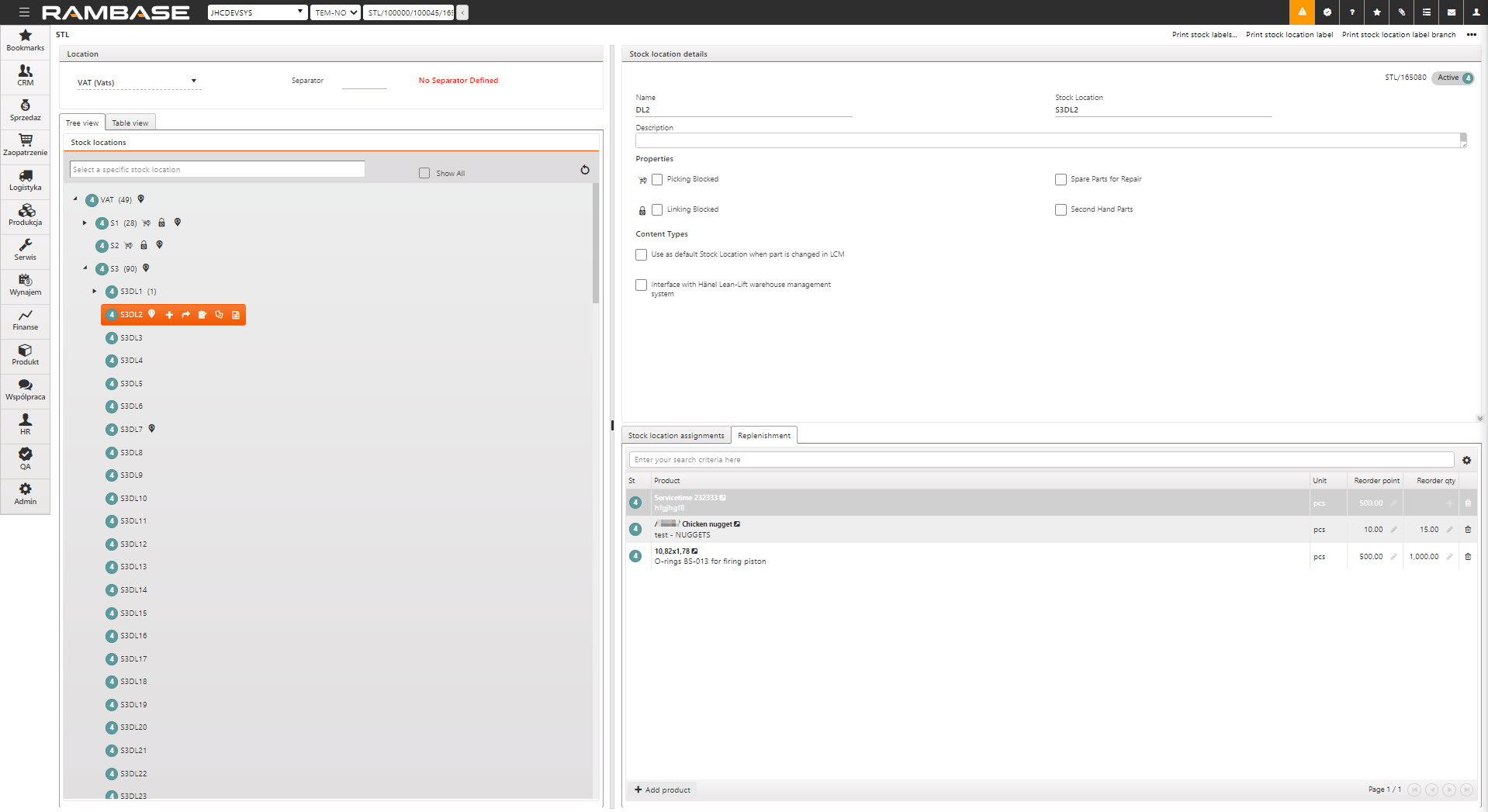

Set Reorder point from the Stock location (STL) application

Highlight the stock location where you want to set a Reorder point in the Stock locations area and click on the Replenishment tab.

Click the Add product button.

Select the Product (ART) in the Product field, set the Reorder point (mandatory) and Reorder quantity (optional).

Click the Create button to set the selected Reorder point for the product in the selected stock location.

It is possible to add/update the Reorder point and Reorder quantity directly in the Replenishment tab, and remove the product.

Set Reorder point from the Product (ART)

Enter the Product (ART) you want to set a Reorder point to.

Click on the Stock location replenishment tab in the Properties area.

Click the Add stock location button.

Select the Stock location (STL) in the Stock location field, set the Reorder point (mandatory) and Reorder quantity (optional).

Click the Create button to set the selected Reorder point for the product in the selected stock location.

It is possible to add/update the Reorder point and Reorder quantity directly in the Stock location replenishment tab, and remove the Stock location (STL).

Export the replenishment file

You can export the file from any level of the Stock location (STL) tree with the Export replenishment file option in the context menu. This will send a excel file (csv) to the user.

This file shows all cases where stock level has reached Reorder point and replenishment should take place. Stock level is calculated based on stock at all stock locations which are "children" of the stock location where Reorder point is defined. In practice for an area.

For example:

Stock location A1 has been set up with Reorder point 100.

At stock location A1B1 there are 10 pcs in stock.

At stock location A1B2 there are 15 pcs in stock.

At stock location A1C3 there are 20 pcs in stock.

Stock level is calculated at 45 pcs. Since this is below Reorder point at the "parent" stock location, the file will show that there is a need for replenishment to stock location A1.