The planning process

Planning, or resource planning, is a process to get the optimal use of the resource capacity and to deliver the product before deadline.

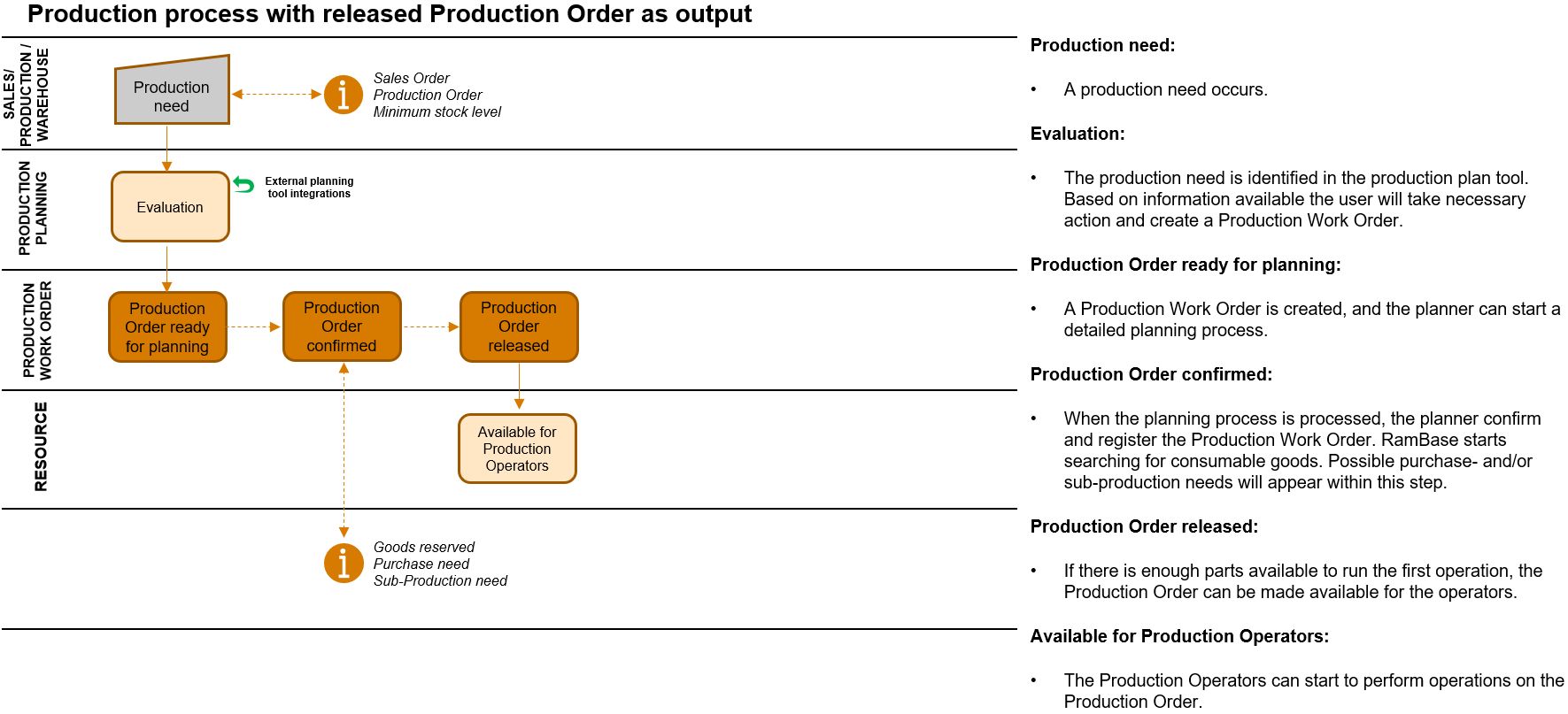

This process may result in

The needs of production is identified.

The needs of production is collated.

The production order is registered.

If a production company does not produce goods itself, most production orders will be initiated by a customer order. This means that the sales department, which receives the customer order, need to hand the planning process over to a production planner, before terms can be agreed upon.

A planning process such as this involves the identification, categorization and prioritization of a production need in sequence. This prioritization books resources such as machines, personnel and any external resources. Planned delivery is then communicated back to the sales department.

This planning phase may also result in several customer orders for the same product to be combined and produced in the same production run. This enables the production company to save production costs and delver at an earlier date.

Tasks relevant for this process

Creating a new production order

Production need is identified through customer orders or orders from the warehouse manager.

Planning production orders

The production order is planned through prioritization, time usage and cost price vs. sales price.

Preparing production orders for production

Production orders ready to start must be ordered by releasing it for the involved resources.