Cost & Time deviation control for production work orders (PWO)

A production company needs some tools to be able to monitor the cost status for a production (project) and also deviations in logged vs planned operation time. Deviations can be caused by simple logging errors by the operator, not realistic planning or problems that occurs and delay processes. It is also important to be able to get alerts for operations where the accrued cost has passed the planned cost + a ‘warning limit’ to follow up possible problems.

Cost deviation control

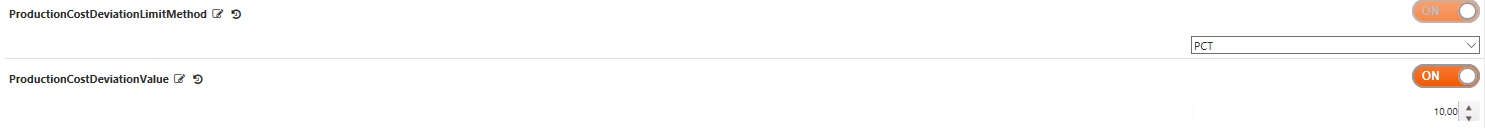

There are two company settings that control the cost deviation limit and alert:

- ProductionCostDeviationLimitMethod : Selectable values: AMOUNT, PCT

One can choose if the cost deviation per operation is to be checked vs a value limit or a percentage limit. Deviation control will run per operation in the Production work order (PWO) Kit.

- ProductionCostDeviationValue : The limit before approval is needed, Amount (in local currency) or Percentage. Format: Decimal.

Calculation method and alert

Calculation:

Each operation within the PWO Kit has a field CostDeviationAmount that is calculated to the operations Planned cost (fixed + variable) * -1 when the operation is started.

The accrued operation cost is increased for each pause of the operation (and by complete operation), and that also reduces the negative CostDeviationAmount.

The CostDeviationAmount is also recalculated if the PWO-Kit is changed (new version).

Formula for calculation: CostDeviationAmount = Accrued cost (Fixed + Variable) - Planned cost (Fixed + Variable).

Each operation within the PWO Kit also has a field CostApprovedValue that is calculated to be:

Planned cost (fixed + variable) + ProductionCostDeviationValue (calculated to amount if PCT is the selected method).

This CostApprovedValue is calculated (set) at the operation when CostDeviationAmount becomes a positive value, which means that accrued cost has become higher than the planned cost.

Formula for first time setting of CostApprovedValue: Planned cost + ProductionCostDeviationValue .

Alert:

Each operation within the PWO Kit has a field CostDeviationAlert . This is a ‘boolean’ field, ‘0’ = false (no alert), ‘1’ = true (alert).

CostDeviationAlert is set to ‘1’ (alert) if CostDeviationAmount > CostApprovedValue - Planned cost.

The program will check if operation should be alerted by each pause/stop of operation and by making new version of the PWO Kit.

NB! Alert is not given if the ProductionCostDeviation*-settings are not used.

CostDeviation Alert handling:

Operations that has CostDeviationAlert = ‘1’ should be checked by cost controller / manager / planner.

Such alerts can be found by / is visible / can be handled in the following applications/views:

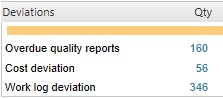

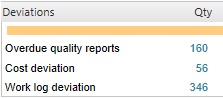

PRODUCTION , the new production overview application:The ‘Deviations’ box will show if such alerts are set.

Click on the number for Cost deviation will open the report Production Cost Deviation Alert that gives cost values. Press ENTER on a line in the report opens the actual PWO where the alert can be handled.

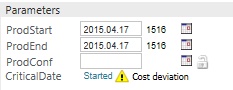

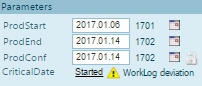

At the production work order (PWO), behind the field ‘CriticalDate’:

The yellow alert icon and the text ‘Cost deviation’ will show if one of the PWOs operations has the alert set.

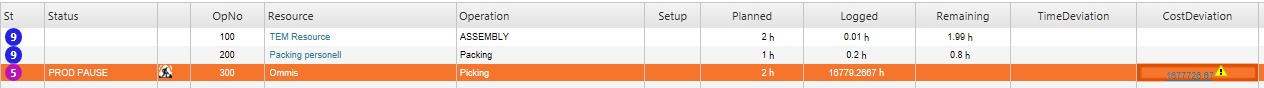

Clicking on the yellow alert icon opens the PWOCRITICALDATE window:

PWOCRITICALDATE (list of the PWOs operations):The column ‘CostDeviation’ shows the CostDeviationAmount and the yellow alert icon at the operation that has the alert set.

Click on the amount to handle the alert, the popup Cost Deviation Approval is opened.

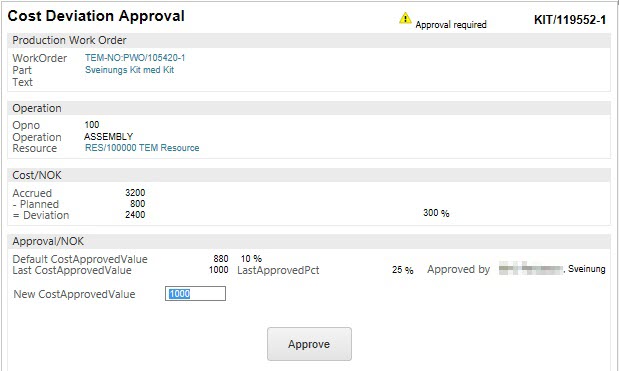

OPRCOSTDEVIATION – popup for cost deviation approval:

Explanation using the above picture as example:

- the Planned cost for this operation was 800 (NOK).

- the ‘default’ CostApprovedValue was calculated to 880 (NOK) because of the ‘settings’ (PCT, 10).

- this operation has had an alert earlier because accrued cost passed the ‘default’ approved value, and the last approved value (Last CostApprovedValue) was set to 1000 by UserId 6610. The alert was then cleared. Each approval will create a record in the revision log at the actual Kit.

- the work is continued, accrued cost is now increased to 3200 (NOK) and new alert is set.

New CostApprovedValue should be set to a value that the operator and manager agree upon and button Approve will set this and clear the alert again.

The Approve button is limited to the permission ApproveProductionOperationCostDeviation and the duty Control and approve production cost.

The ‘shopfloor’ application ‘MACHINEHOURS’:

Cost deviation shows in the mid of the screen and the popup for viewing details / approve is opened by clicking on the amount.

Work log Deviation Control

The purpose of the work log deviation alert is to easily find and control completed operations (Status 9) where the difference between the planned work time and the total logged work time is below or above the decided thresholds. This makes it easier to find operations where the operator has forgotten to start / stop in time and where the actual work time differs much from the planned time.

Calculation:

The field WorkLogDeviationPct at each operation is calculated when the operation is completed (KITOPST =>9).

Formula: (logged time – planned time) * 100 / planned time.

So the WorkLogDeviationPct is the deviation time in percentage when comparing logged and planned time.

Examples:

- Planned 10 hours, worked 8.5 hours: WorkLogDeviationPct = - 15

- Planned 10 hours, worked 11.5 hours: WorkLogDeviationPct = 15

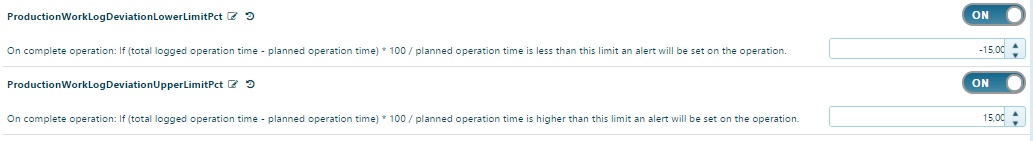

There are two company settings that control the work log deviation limit and alert:

- ProductionWorkLogDeviationLowerLimitPct: Should have a low negative value, e.g. - 15.

If the calculated WorkLogDeviationPct < this limit: work log alert will be set by complete operation, logged operation time is too low compared to planned time and below the limit for setting the alert.

- ProductionWorkLogDeviationUpperLimitPct: Should have a low positive value , e.g. 15.

If the calculated WorkLogDeviationPct > this limit: work log alert will be set by complete operation, logged operation time is too high compared to planned time and above the limit for setting the alert.

Alert:

Each operation within the PWO Kit has a field WorkLogDeviationAlert . This is a ‘boolean’ field, ‘0’ = false (no alert), ‘1’ = true (alert).

WorkLogDeviationAlert is set to ‘1’ according to the rules and settings described above under ‘Calculation:’.

The program will check if the operation should be alerted by making new version of the PWO Kit and if logged operation time is adjusted manually by the available tool for this.

NB! Alert is not given if the ProductionWorkLogDeviation*-settings are not used.

WorkLogDeviation Alert handling:

Operations that has WorklogDeviationAlert = ‘1’ should be checked by cost controller / manager / planner.

Such alerts can be found by / is visible / can be handled in the following applications/views:

PRODUCTION , the new production overview application:The ‘Deviations’ box will show if such alerts are set.

Click on the number for ‘Work log deviation’ will open the report ‘Production Time Deviation Alert’ that gives some cost values and time values. Pressing ENTER on a line in the report opens the actual PWO where the alert can be handled.

At the Production work order (PWO), behind the field ‘CriticalDate’:

The yellow alert icon and the text ‘WorkLog deviation’ will show if one of the PWOs operations has the alert set. Clicking on the yellow alert icon opens the PWOCRITICALDATE window:

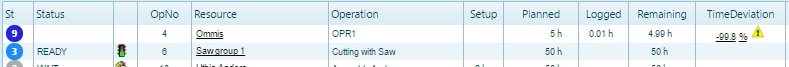

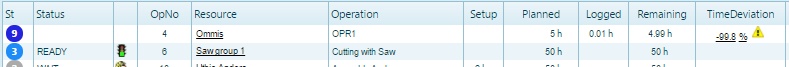

PWOCRITICALDATE (list of the PWOs operations):The column ‘TimeDeviation’ shows the WorkLogDeviationPct and the yellow alert icon at the operation that has the alert set.

Click on the value to handle the alert, the popup ‘Worklog Deviation Details’ is opened.

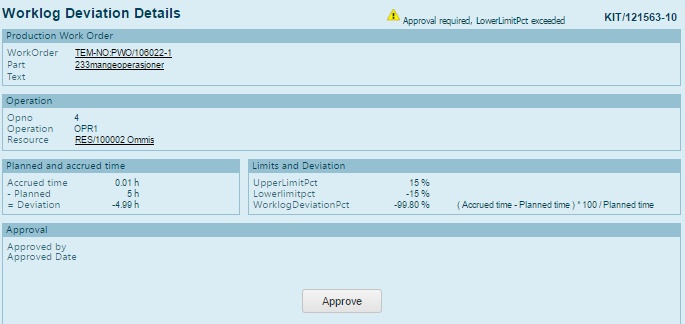

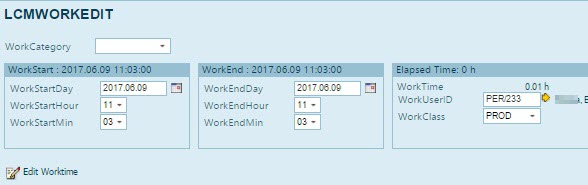

OPRWORKLOGDEVIATION – popup for worklog deviation details and approval:

Explanation using the above picture as example:

- the Planned time for this operation was 5 hours.

- the operation was completed and total logged time is 0.01 hours. WorkLogDeviationPct was calculated to -99.80 and that is lower than the ProductionWorkLogDeviationLowerLimitPct (-15).

- this operation has therefore WorklogDeviationAlert = ‘1’.

There are two options to handle this alert:

The deviation is ok, no need to adjust the logged operation time:

Click on the Approve button. The alert is switched off and will be logged in the KIT revision history. The Approve button is limited to the permission ApproveProductionOperationTimeDeviation and the duty Control and approve production cost.

The logged time should be changed (forgot to start or stop in due time):- Press ESCAPE from the popup, back to:

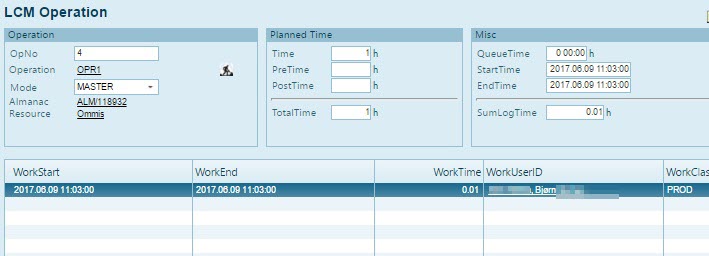

- Pressing ENTER on the line with the alert opens the worklog list for the operation:

- Press Enter on the line that should be adjusted:

Click on the Edit Worktime icon to adjust the logged time. This will recalculate total logged time, the WorkLogDeviationPct and the WorklogDeviationAlert.

The ‘shopfloor’ application ‘MACHINEHOURS’:

Worklog deviation shows in the mid of the screen and the popup for viewing details / approve is opened by clicking on the amount.