Sales and operation planning (SOP)

Sales and operations planning (SOP) is a planning tool that takes the sales forecast and creates a plan for production and purchasing to meet the sales requirements.

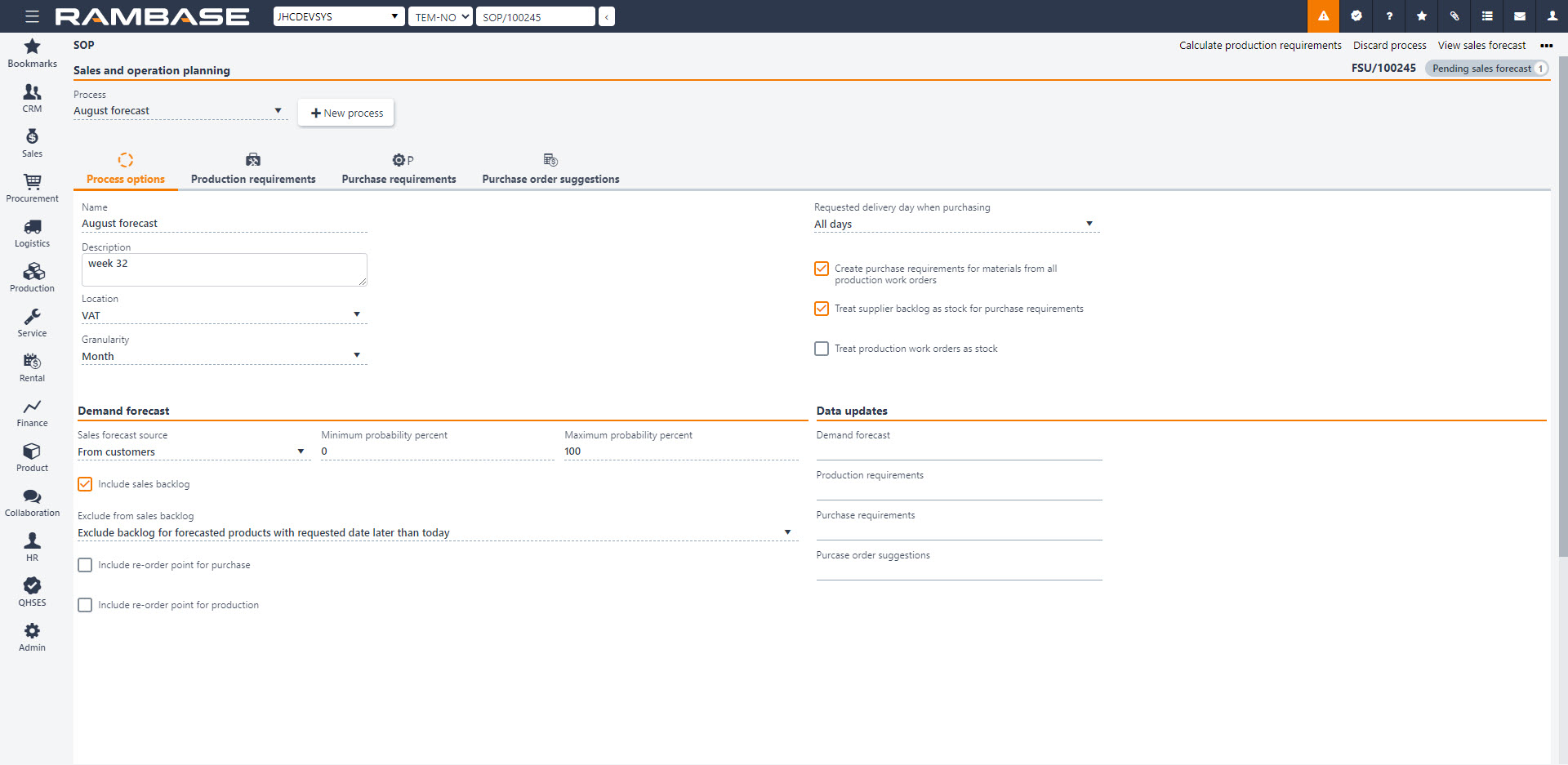

Description of the tab overview below:

Process options

This tab contains all information regarding the planning process.

General options:

Name field

Text field for entering a name for the process.

Description field

Text field for optional description.

Location drop-down menu

Location identifier

Granularity drop-down menu

Granularity used to present the different plans in the Sales operation planning process, either by week or month.

Requested delivery day when purchasing drop-down menu

Preferred day of delivery. Used to consolidate purchase order suggestions. Default is all days.

Create purchase requirements for materials from all production work orders checkbox

By enabling this option, materials from all ongoing and planned production work orders are included as gross purchase requirements. This means that you might get purchase requirements for materials belonging to production work orders not related to the production requirement plan. If this option is disabled, only materials needed to fulfill the production requirements are included as gross purchase requirements.

Note

Note that even if this option is disabled you will still get purchase requirements for materials in ongoing and planned production work orders (PWO) consumed by (net off) the production requirements.

Treat supplier backlog as stock for purchase requirements checkbox

By enabling this all purchase orders and purchase order responses will be treated as stock. Any purchase orders and purchase order responses confirmed in the future (ex. in two months) is available from today and can be used to net off purchase requirements. By not enabling this, you might end up with purchasing products that could instead be acquired by requesting change of delivery date on existing supplier backlog.

Treat production work orders as stock checkbox

By enabling this, existing, but not completed, production work orders will be treated as stock. Any production work orders can be used to net off production requirements. By not enabling this, you might end up with creating new production work orders instead off re-planning already existing production work orders.

Demand forecast area

Sales forecast source drop-down menu The source to use from the sales forecast.

Include sales backlog checkbox

If sales backlog is included, everything from the backlog is added to the demand forecast. Note that backlog from products sales forecast by customers (through the sales forecast source), will not be included.

Minimum and maximum probability percent field

Minimum and maximum probability in percentage to include from the sales forecast

Include re-order point for purchase checkbox

If products which are purchased have specified re-order point quantity for the location used in the Sales and operation planning process, the re-order point quantity will be added as a demand. This will then be included in the gross quantity of the purchase requirements. Note that this also includes products with product structures manufactured externally.

Include re-order point for production checkbox

If products which are manufactured have specified re-order point quantity for the location used in the Sales and operation planning process, the re-order point quantity will be added as a demand. This will then be included in the gross quantity of the production requirements. Note that this does not includes products with product structures manufactured externally.

Demand forecast

Date and time demand forecasts were created

Production requirements

Date and time production requirements were updated for this Sales and operation planning process.

Purchase requirements

Date and time purchase requirements was updated in this Sales and operation planning process.

Purchase order suggestions

Date and time purchase requirements was updated in this Sales and operation planning process.

Production requirements

This tab shows all production requirements which follows the sales forecast. Each production requirement represents a product and a requested delivery date.

Key fields are:

Updated at

Date and time production requirements were updated.

Requested delivery date

The delivery date as requested.

Product

The required product

Available quantity

Total quantity available to be subtracted from the demand quantity (gross quantity). This is the sum of all goods receptions and production work orders ready to be consumed at requested delivery date.

Gross quantity

Gross quantity of the production requirement. This is the total demand before any subtractions or adjustments is considered. Initially set as the sales forecast quantity, but will be changed if the net quantity of parent product structures changes.

Adjusted quantity

Quantity adjusted by the users. Can be both negative and positive. The sum of gross quantity and adjusted quantity can never be less than zero.

Subtracted quantity

Quantity of stock and production work orders subtracted from the gross quantity.

Production adjusted quantity

Some products are only produced in multiple of a specified quantity. In that case, the net quantity might need an adjustment.

Net quantity

Net production requirement quantity. This is calculated by subtracting production work orders, stock and adjusted quantity from the gross quantity.

Treat production work orders as stock

By enabling this, existing, but not completed, production work orders (PWO) will be treated as stock. Any production work orders can be used to net off production requirements. By not enabling this, you might end up with creating new production work orders instead off re-planning already existing production work orders.

Purchase requirements

This tab shows all the purchases required to fill the orders. Each purchase requirement represents a product and a requested delivery date.

Options related to purchase requirements:

Treat supplier backlog as stock

By enabling this all purchase orders and purchase order responses will be treated as stock. Any purchase orders and purchase order responses confirmed in the future (ex. in two months) is available from today and can be used to net off purchase requirements. By not enabling this, you might end up with purchasing products that could instead be acquired by requesting change of delivery date on existing supplier backlog.

Require materials from all production work orders

By enabling this option, materials from ALL ongoing- and planned production work orders are included as gross purchase requirements. This means that you might get purchase requirements for materials belonging to production work orders not related to the production requirement plan. If this option is disabled, only materials needed to fulfill the production requirements are included as gross purchase requirements. Note that even if this option disabled you will still get purchase requirements for materials in ongoing- and planned production work orders consumed by (net off) the production requirements.

Key fields are:

Updated at

Date and time purchase requirements were updated

Requested delivery date

The delivery date as requested by the customer.

Product

The required product.

Available quantity

Total quantity available to be subtracted from the gross quantity. This is the sum of all goods receptions, purchase orders and purchase order responses ready to be consumed at requested delivery date.

Gross quantity

Gross quantity is initially the same as the sales forecast quantity but might have changed during the production requirement planning. The gross quantity is the final required quantity for given product at requested delivery date.

Subtracted quantity

Quantity of stock, purchase orders and purchase order responses subtracted from the gross quantity.

Net quantity:

Net purchase requirement. This is the quantity needed to be ordered for this product at this requested delivery date. The net quantity is calculated by subtracting stock, purchase orders and purchase order responses from the gross quantity.

Purchase order suggestions

This tab creates purchase orders for all the purchase requirements, based on the information from the Sales and operation planning (SOP). Each purchase order suggestion represents a product and a requested delivery date.

Options related to purchase order suggestions:

Requested delivery day

Preferred day of delivery. Used to consolidate purchase order suggestions. Default is all days.

Each purchase order suggestion represents a product and a requested delivery date.

Key fields are:

Updated at

Date and time purchase order suggestions were updated.

Requested delivery date

The delivery date as requested.

Product

The required product.

Supplier

The suggested supplier.

Suppliers product name

Suppliers product name.

Lead time

Lead time for product and suggested supplier.

Deadline date

Deadline for purchasing product from supplier. Calculated by subtracting lead time from requested delivery date.

Quantity

Quantity suggested to purchase.

Gross purchase price

Gross price of the purchase order suggestion.

Gross requirement quantity

The gross demand for supplier, product and requested delivery date.

Subtracted requirement quantity

Quantity from open purchase orders and purchase order responses subtracted from the gross demand quantity to get the net demand quantity.

Net requirement quantity

Net demand quantity for this product, supplier and requested delivery date. The net quantity is the current demand, and will be the base for creating the quantity of the purchase order suggestion.