Stock location (STL)

The Stock location (STL) application is used to create stock locations in a tree structure, in addition to managing your existing warehouses. To open the Stock location (STL) application, click on Logistics in the RamBase menu and then click on Warehouse management. Click on the Stock location to enter the Stock location (STL) application.

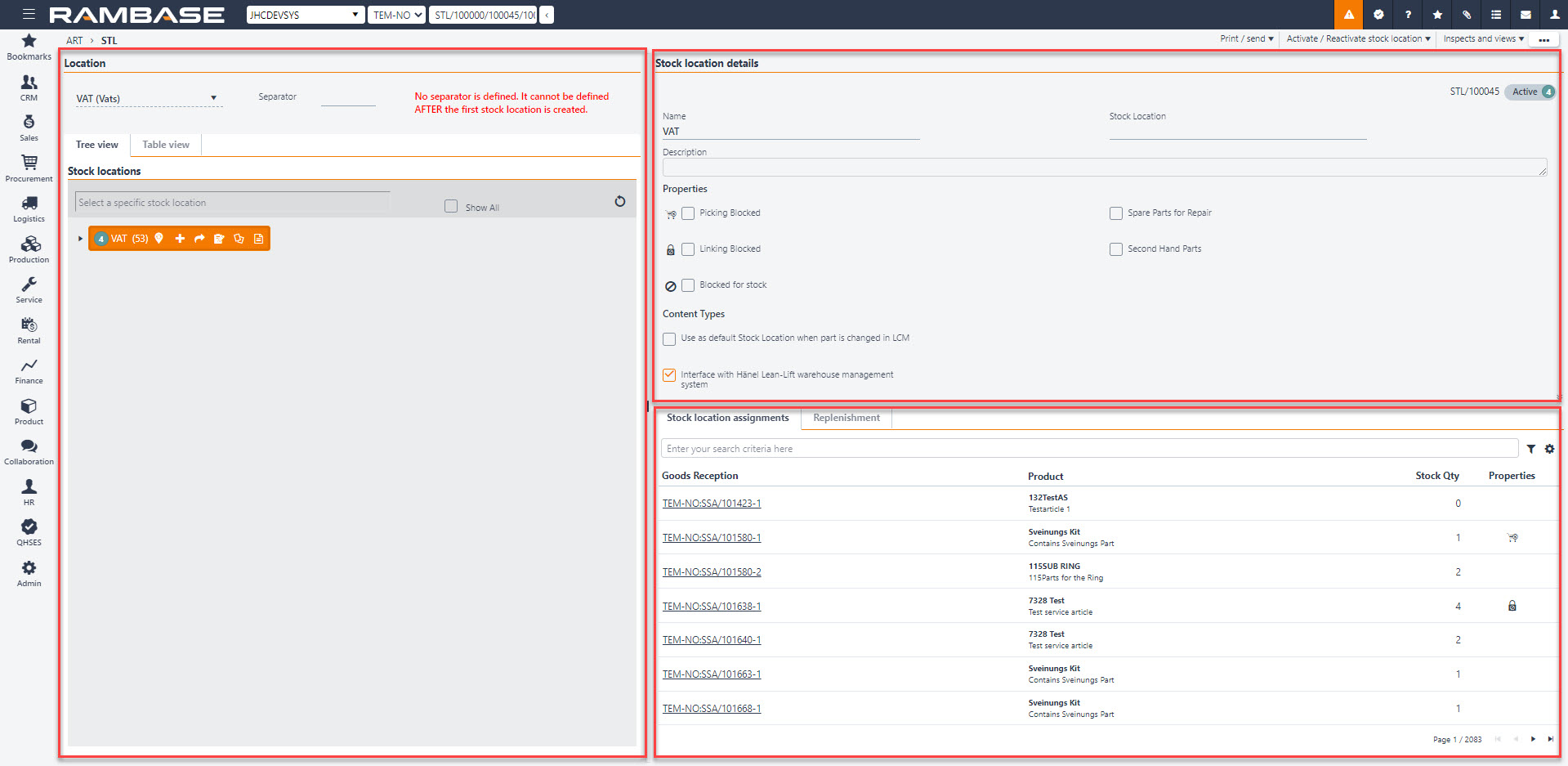

Main areas

There are three main areas in the Stock location (STL) application:

Location area

The Location field shows the warehouse location, which is the top level. The level below is shown in the Stock location field, which is the location within the warehouse. The item lines below these fields show the contents of the Stock location (STL). These results can be filtered using the filter. The Separator field is used to define the symbol or character that separates the identifiers in the location name.

Note

It is important to define the separator before starting creating stock locations, because afterwards it will not be allowed.

Stock location details area

This area displays several fields related to the Stock location (STL) and any description added. Including these check boxes:

Picking Blocked

If this is checked, all products which are moved in to the Stock location (STL) are locked by default and cannot be picked.

Linking Blocked

If this is checked, all products which are moved to this Stock location (STL) are blocked from being assigned in the Assignment Register (SAR).

The only exception is Stock correction (SAW).

A Stock correction (SAW) can always be created for goods placed on a Stock location assignment (SAP), which is blocked for linking.

Blocked for stock

If this is checked, goods cannot be moved to the selected Stock location (STL).

Spare parts for repair

This checkbox is used to indicate that the goods in this Stock location (STL) can only be used as spare parts to be used in repairs. This option automatically blocks linking.

Second hand parts

Second hand parts are parts which are returned or blocked from being sold or used in productions for any reason. Choosing this option for the stock location blocks the items for linking and picking.

Content Types

Use as default Stock Location (STL) when part is changed in Life cycle (LCM): Will be used as suggested Stock location (STL when part is changed in Life cycle (LCM).

Tabs

Stock Location Assignments tab

This area gives you an overview over all Stock assignment (SAP) documents in this Stock location (STL).

Replenishments tab

This area is used for setting a reorder point (required minimum stock level) for a product at a specific stock location. This is designed for cases where the replenishment should take place by an ordinary move of goods between Stock locations (STL) within one Location (LOC). It is not designed for refill by goods transfer from other locations, nor by purchase of products.

Read more about setting a Reorder point for a product in a specific stock location here.

Print Stock location labels in Stock location (STL) application

By clicking on the context menu, you will get two different choices to print stock labels for warehouse shelves and areas.

Print stock location label

Prints the highlighted stock location label

Print Stock location label branch

Prints the full amount of stock location labels