Reception

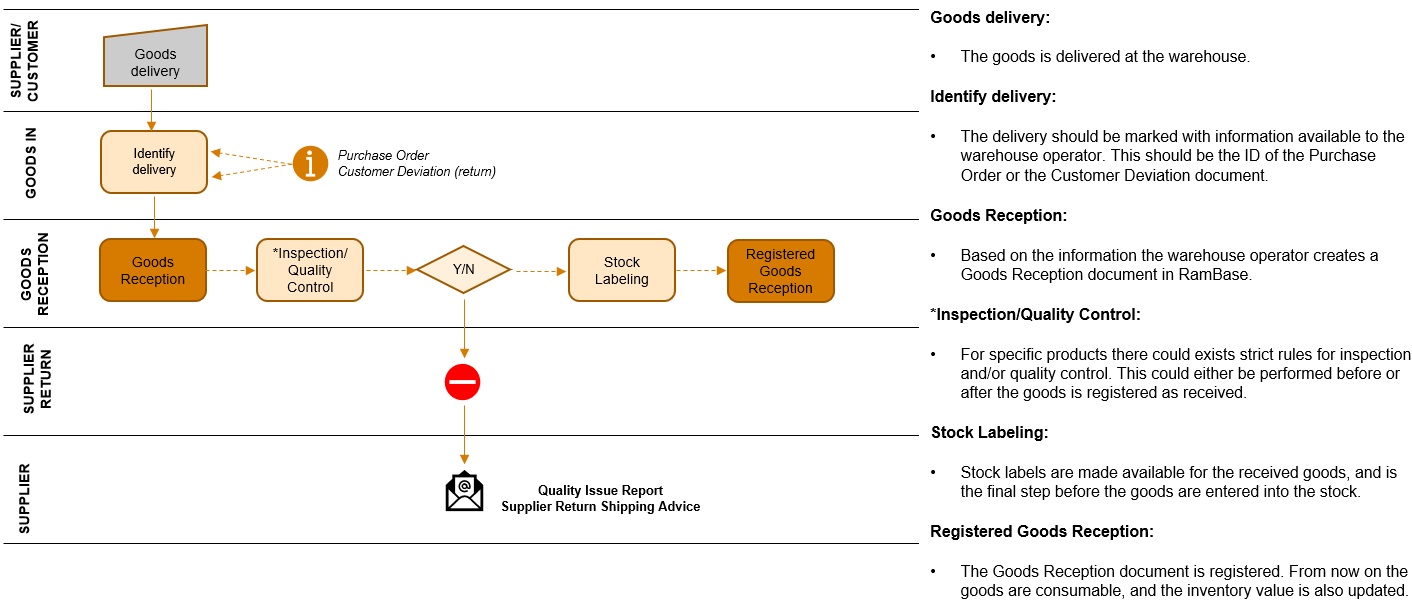

The reception process is where goods related to purchase orders are received.

Output from the reception process

Documentation prepared for goods coming into stock.

Tracking of goods expected to be delivered to stock.

Goods registered into stock.

Correct goods reception is a prerequisite for the efficient function of warehouse processes. The goods reception is performed by personnel, either manually or by assistance of electronic equipment such as handheld terminals. Incoming goods related to purchase orders are received, inspected and put into stock. If a company is losing the traceability within the warehouse, or the link between the warehouse and an ERP-system, it may have unfortunate consequences. A low turnover in the stock is not good for the economy, a lost traceability for goods in stock is not good for the delivery performance, and a lack of inspections and quality control may result in high amount of reported deviation cases.

Tasks involved in this process

Create waybill in

The forwarder of the shipment may be registered upon a shipping consignment.

Perform inspection control of goods

All, or parts of the received goods, may be inspected before they are put to stock.

Print stock labels

If the goods must be labeled before putting to stock, the warehouse worker may print stock labels.

Put goods into stock

Goods are physically put to internal stock locations and must also be registered as available, or at least "received".