Production

A production is the process where something is produced using resources and operations.

This process may result in

Finished produced product.

Modified product.

Scrapped product.

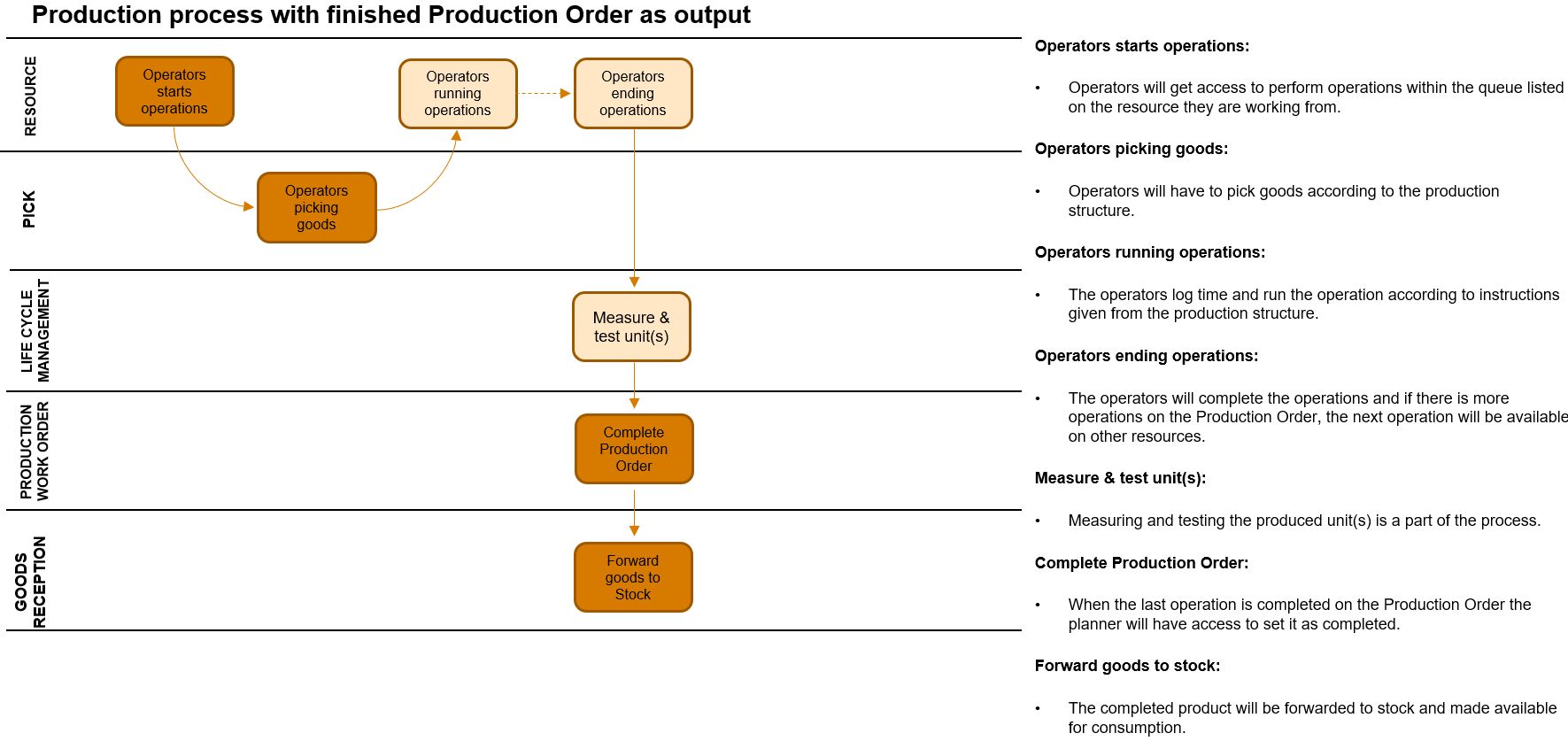

There are several phases one needs to take into consideration during a production. Resources and operations need to be prepared, such as warming up machines, programming machines or maintaining them. Another situation may be workers who need to read instruction manuals, drawings or other relevant documentation.

The production phase is also divided into different steps. If you need raw materials for a production, these needs to be picked from the warehouse, for example circuit boards, screws, frames and other necessities need to be picked to produce a computer screen. Every step is logged into the system to keep track of the production process. Another important step is to log all used hours during the production, including picking, measuring, quality testing and other actions. In our example, a computer screen needs to be checked for picture and color quality.

This, together with the cost of goods, will create an overview of the total cost of the product. The combination of raw material costs, worked hours and profit margin will then create the base for sales price, modification or scrapping.

Tasks relevant for this process

Pick job

There will most likely be several production orders waiting for the same resource. The jobs are the set in a priority queue and picked by certain criteria.

Logging work hours

Work hours used per operation or per production order needs to be registered.

Confirming picking from warehouse

Goods to be included in the production needs to be picked from warehouse, and the production operator needs to confirm the pick.

Performing testing and quality check

Produced goods needs to be tested and quality checked to ensure they are ready for delivery.

Finishing production

After the produced goods have been tested and marked as ready for delivery, it needs to be freed and marked done.